Before Calibrating an Instrument Why is calibration and proper maintenance a critical process for instruments to ensure the accuracy of the measurement, reading & testing results? After long usage, environment exposure or if the testing and measuring instruments are not properly calibrated… They will eventually produce measurement errors, uncertainty, bias (zero drift) and sensitivity drift. Thus […]

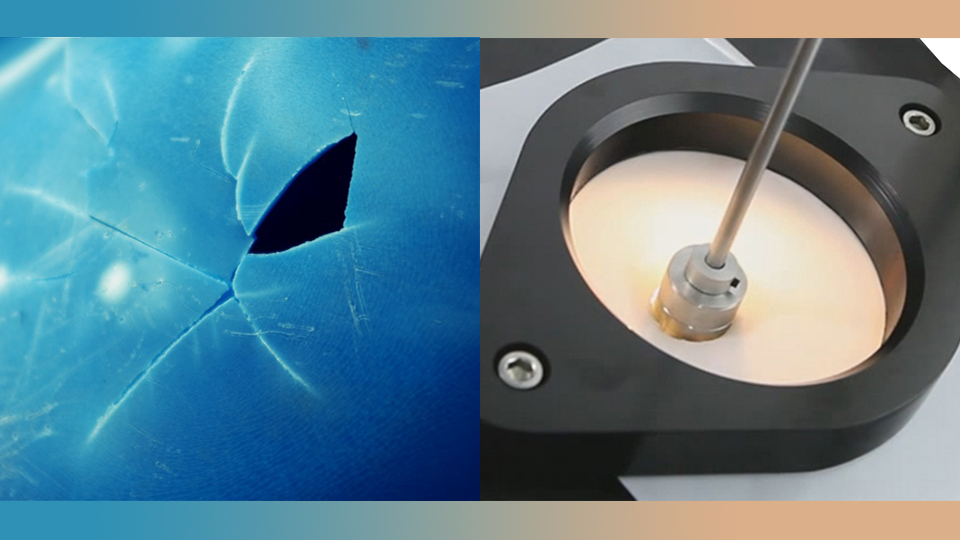

View original post here. Free-Falling Dart Impact Test is a material degradation simulation process that can evaluate the impact strength and toughness of the test sample (to do quality comparison on their end-products and raw materials). This allows manufacturers from the R&D and QC sector of laboratories, packaging, inspection, plastic film manufacturing and other related sectors, to study the impact resistance and […]

Fill your Food Packages with Speed “Packaging has been an important part factoring the way a brand is imaged and how the products will be sold. But what are packaging for if they are not properly filled up?” Depending on your company’s needs with filling spices, powder, beans, or other dry goods into packets, packs, bags […]

Evaluate Coat Corrosion with Salt Spray Test “Can Your Coating Withstand Corrosion Attack From Short-Term & Lon-Term Deterioration Or Environmental Exposure?” What is Salt Spray Test? Salt spray testing is commonly used to determine the corrosion resistance of the substrate (coated material) and its surface coatings. Commonly used in marine, automotive, aircraft, metals and other industries that uses finishing […]

When is Calibration Due? Calibration is crucial to adjust and maintain the accuracy and precision of measuring & testing instruments. The manufactured quality of the components, parts and products produced is determined by the calibration done on them. To ensure consistency and reliability of the measuring equipment. When? The general recommendation is an interval 12 months period. How Often? […]

Choose the Right Heat Treatment Furnace “Picking the most suitable furnace for an industrial application requires knowledge of the factors & processes needed for the manufacturing & production lines.“ An industrial furnace goes up to 1000°C – 1200°C or higher. Allowing manufacturers to use for its heating & cooling capability on various materials (e.g. metals) […]

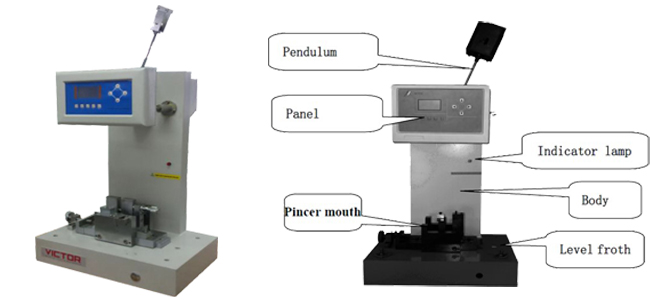

“A material’s toughness determines if it is suitable to be reused for production or to improve its manufacturing quality for their end-product.” Pendulum Impact testing is a type of mechanical testing used to study the toughness of a material to check the product’s ability to absorb impact and to analyse the deformation process before fracturing (by using a falling pendulum weight […]

Having trouble with visual colour checking? Need accurate colour reading? Before colour is painted, printed and produced, manufacturers have to ensure that colour is monitored and accessed during the design stage, the formulation & production process and finally during the quality control process. Which determines the overall outlook on the products while attracting customers… After […]

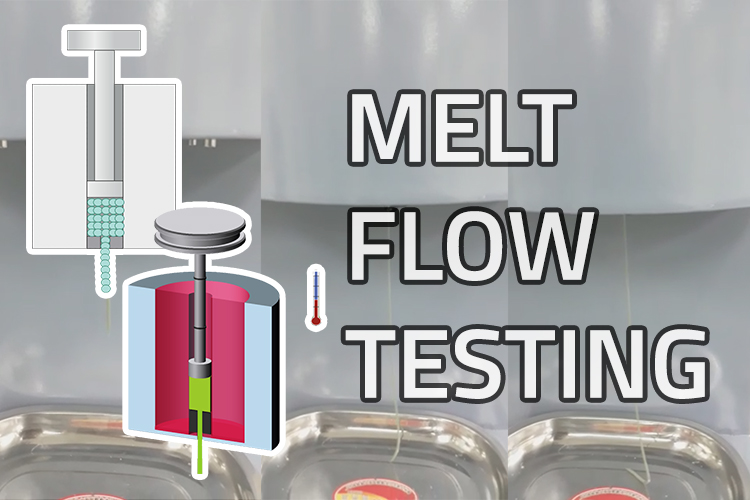

View Original Post, HERE. Melt Flow Testing – An Introduction Melt flow testing measures the ease of flow on the melted thermoplastic* to predict how their resins/pellets will behave in their intended applications. This allows product designers, researchers, manufacturers, and even quality control managers to discover the overall quality and production rate capability of that polymer. *A type of polymer that […]

View Original Post, HERE. Suitable items for Calibration… Are your measuring tools functioning properly? Want to achieve 100% accurate reading on measurement? By regularly calibrating measurement equipment and monitoring their performances and end result. This ensures that the measuring instrument can conform to : International standards Measure accurately and consistently; Accordingly to its specifications. After proper calibration, satisfaction is […]