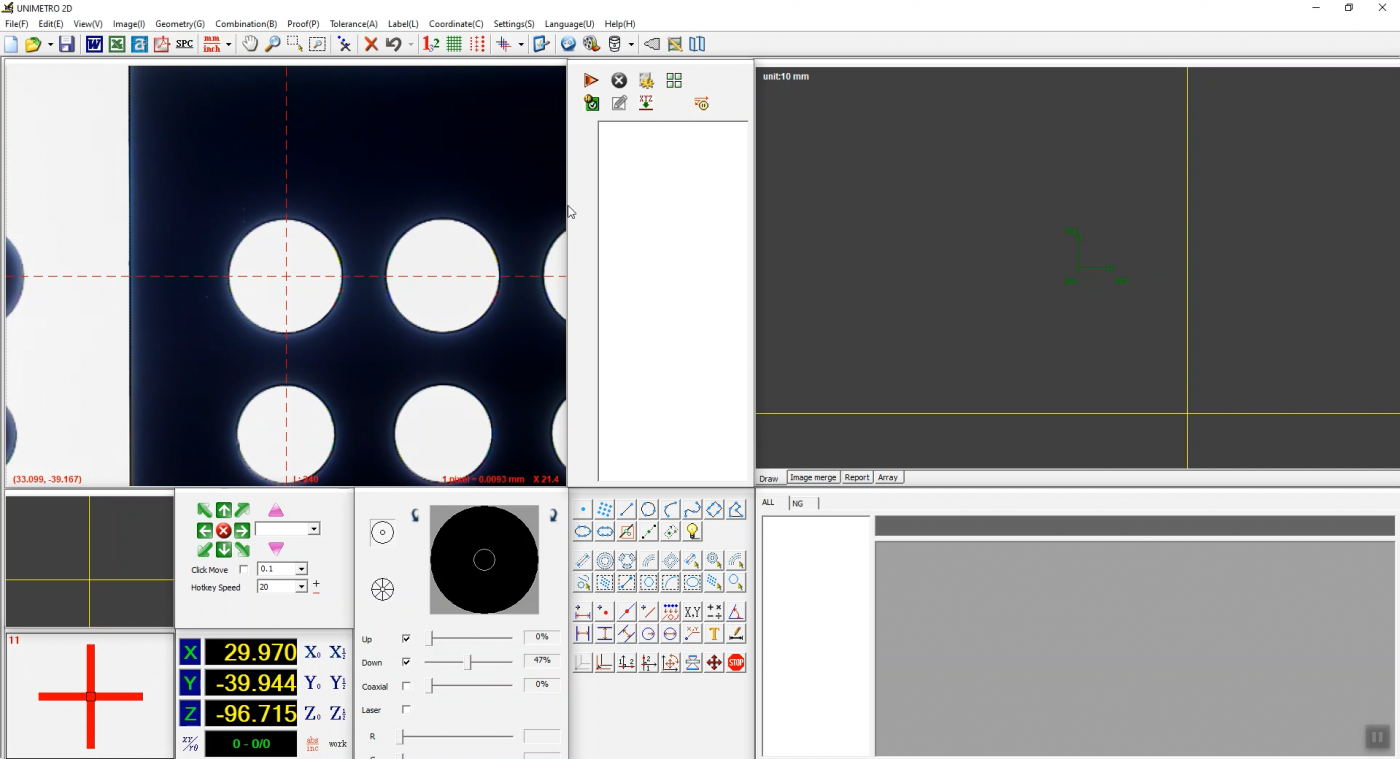

Today, we will discuss about the steps to operate the VMS and things to know during the operation. To operate VMS, we need to understand the basic of computer-aided-drawing (CAD) and metrology to ensure the best measurement results. The measurement process of VMS is mainly based on the metrology software as most of the features are only accessible via the software. Now, let us see what the procedures is to perform measurement on VMS.

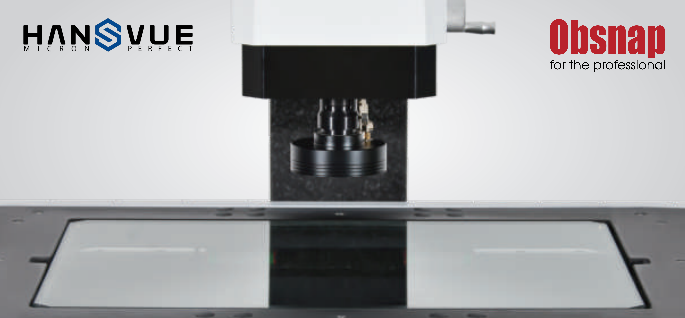

There are several series and model of HANSVUE Vision Measurement System for different measuring application and end users from different industries. It is crucial to select a suitable model in order to ensure the best user experiences and the accurate measurement results. Here we will discuss all the series of the HANSVUE VMS including series such as BASIC, EXTRA, PEAK, ULTRA and HE.

We had discussed what is a VMS and how it works in our previous articles. Today, we will discuss the application of a VMS and why that is a need of VMS. In our daily life, we can use a ruler, calliper, protractor ruler or measuring tape to measure the dimension and angle of an object. These methods can be simply classified as contact measurement.

Video Measurement System is sometimes known as the vision measurement system. It is a machine that is designed for non-contact measurements of small and precision parts. VMS is commonly used in industries, such as electronics, automotive, plastic injection, metal, and part assembly where high accuracy, precise and consistent measurements are essential requirements for their products. One of the famous brands of VMS in Malaysia is HANSVUE.