Video Measurement System is sometimes known as the vision measurement system. It is a machine that is designed for non-contact measurements of small and precision parts. VMS is commonly used in industries, such as electronics, automotive, plastic injection, metal, and part assembly where high accuracy, precise and consistent measurements are essential requirements for their products. One of the famous brands of VMS in Malaysia is HANSVUE.

In fact, VMS have been around the industry for more than 40 years. It was a technology adapted from profile projector. The first VMS was developed in year 1977 by an engineering company in USA. Today, VMS is evolved to have CCD digital camera, magnification lens, faster processors, laser/contact probe, improved metrology software with better ability to perform CAD drawing, measurement, and statistical analysis.

Profile Projector

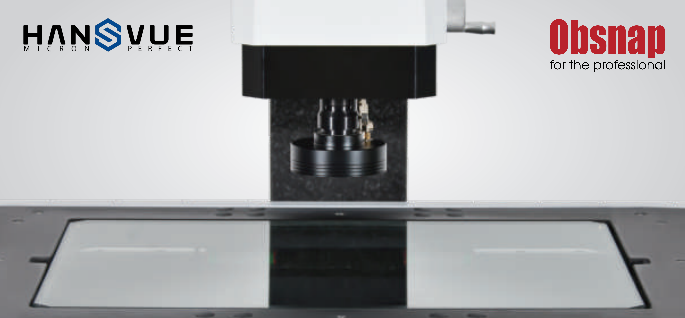

HANSVUE VMS ULTRA400

There are many types of VMS available in the market. Basically, they can be divided into two types, the manual or CNC automated types of VMS. For manual type, the movement of the workbench and the camera system need to be controlled by manually rotating the travel knobs. Meanwhile, for the CNC automated type, it is equipped with servo motors at workbench for X & Y-axis movement and camera system for Z-axis movement.

The CNC automated VMS can be easily controlled by the joystick controller or even programmed using metrology software to perform measurements automatically. A CNC system is best suited when large number of test pieces need to be measured. For HANSVUE, we have 3 different series of VMS for different applications which are the BASIC, ULTRA and HE series.

HANSVUE VMS series: ULTRA, HE, BASIC

The basic components of a video measurement system are

- CCD digital camera system,

- LED lighting sources,

- workbench,

- and a computer.

An ideal VMS would have the best straightness of travel, optimal moving speed of the work stage and high-resolution camera to provide precise and accurate measurements.

HANSVUE VMS ULTRA300

The workbench consists of two parts, a glass work stage, and a granite base. The work stage can move in both X and Y-axis. These mechanical parts are normally integrated with the camera system. This ensures that no part of the VMS moves independently of the other because if it does it will greatly affect the measurements.

The camera system and the LED lighting sources are protected in a metal hood. They are held above of the workbench with a pillar to capture the images of the test piece placed on the work stage. The LED lighting sources are to produce a shadow effect and contrast the image of the test piece to be clearer and sharper.

Metrology Software

After the clear image of test piece is captured, the image can be processed using the metrology software in the computer.

- A good metrology software can perform image inspection, image enhancement, image filtering, image calibration, and image locating.

- These functions are important to sharpen edges of the image, remove noises, removes non-linear and perspective errors caused by lens distortion and camera placement.

- The locating features is essential for aligning objects and determining exact object placement.

- These functions can be found in the UNIMETRO 2D, it is a metrology software designed for HANSVUE VMS. The user can use it to perform automatic detection, measurements by using the geometric function tools and more.

Metrology Software

Let’s us see how a VMS works. The VMS does not measure an object directly but measure the image of the object.

- The image of the object will be magnified until the edges and lines can be see clearly.

- The displacement of the object can be calculated using the X and Y-axis movement of the work stage.

- With the help of the metrology software, the dimension, angle, position, and height/depth of the test piece can be measured.

- Moreover, the VMS can be integrated with a touch probe for specific applications such as 3D measurements. A touch probe can reach out to hidden features that cannot be accessed by illumination.

In the nutshell, HANSVUE VMS is a very powerful machine for small and precise part measurements.

HANSVUE is a VMS that can provide an automatic, fast measurements process and providing an accurate, precise, and consistent measurements. Besides, it is user intuitive and easy to operate. With the help of VMS, it can greatly increase the effectiveness and efficiency of the measurements.