“Quality control for metals & alloys are critical to ensure structure integrity and reliability for the manufacturing use and consumer application…” Benefits of Metallographic Sample Preparation: Analysing the microstructure of the physical structure and components material (with microscopy). Determine if the material has been made/processed correctly Discovering why a material’s quality passed or failed during application & […]

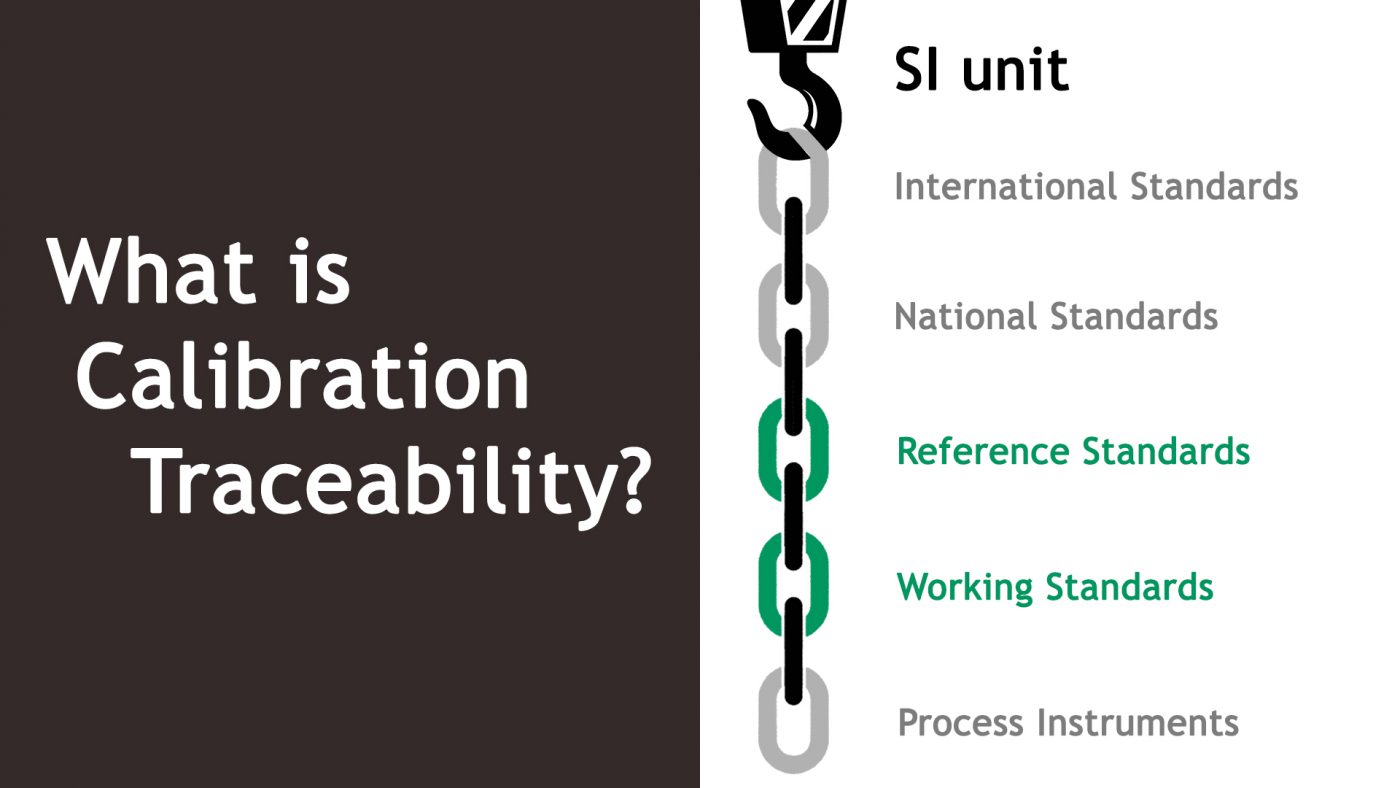

The Importance of Calibration Traceability “A calibration performed on an instrument, can become pointless if it cannot be traced to a known reference / standard.” Traceability is defined by the measuring result and whether its value can be compared and related to a working standard or reference. This can be done through a referring to an […]

“Wishing you a joyous, Eid Adha!” From, Obsnap Group of Companies NOTICE: We are closed on 12th August 2019 (Monday) We’ll be back on 13th August 2019 (Tuesday)

“RoHS directive encourages manufacturers to reduce the use of hazardous & toxic materials to ensure user safety and product reliability while preventing future environment pollution.” Benefits of RoHS Directive & Certification Complying with the RoHS directive can encourages manufacturers to: Contribute to a cleaner environment with stricter quality process control, overall reduced number of […]

“Non-destructive measuring instruments like the wall thickness gauge and the ultrasonic thickness gauge, has helped many manufacturers to perform thickness measurement without damaging their products.” Importance of Thickness Measurement Manufacturers can ensure their users’ safety, convenience and product reliability by checking on the thickness of their product. To avoid structure failure & to identify […]

Before Calibrating an Instrument Why is calibration and proper maintenance a critical process for instruments to ensure the accuracy of the measurement, reading & testing results? After long usage, environment exposure or if the testing and measuring instruments are not properly calibrated… They will eventually produce measurement errors, uncertainty, bias (zero drift) and sensitivity drift. Thus […]

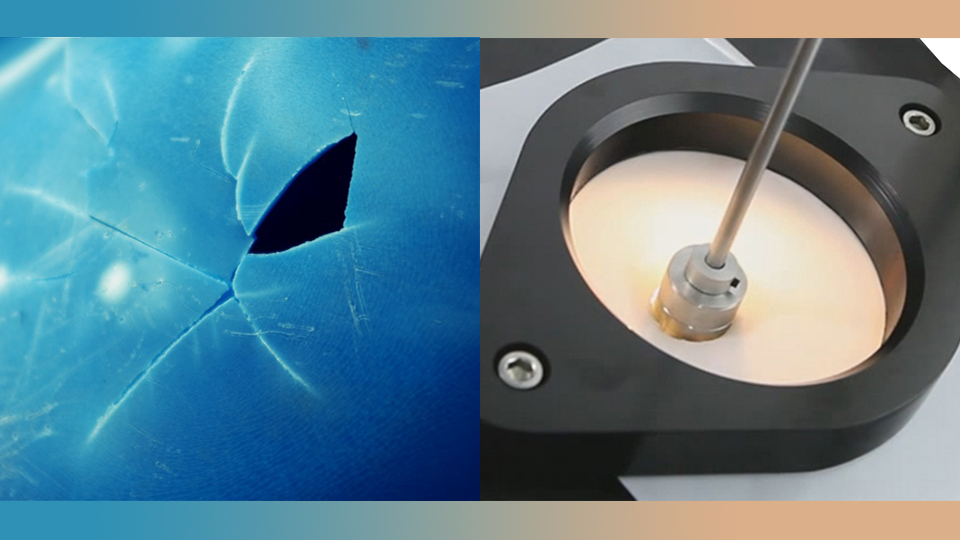

View original post here. Free-Falling Dart Impact Test is a material degradation simulation process that can evaluate the impact strength and toughness of the test sample (to do quality comparison on their end-products and raw materials). This allows manufacturers from the R&D and QC sector of laboratories, packaging, inspection, plastic film manufacturing and other related sectors, to study the impact resistance and […]

Fill your Food Packages with Speed “Packaging has been an important part factoring the way a brand is imaged and how the products will be sold. But what are packaging for if they are not properly filled up?” Depending on your company’s needs with filling spices, powder, beans, or other dry goods into packets, packs, bags […]

Evaluate Coat Corrosion with Salt Spray Test “Can Your Coating Withstand Corrosion Attack From Short-Term & Lon-Term Deterioration Or Environmental Exposure?” What is Salt Spray Test? Salt spray testing is commonly used to determine the corrosion resistance of the substrate (coated material) and its surface coatings. Commonly used in marine, automotive, aircraft, metals and other industries that uses finishing […]

Event Name: Msia Plas 2019

Date: 18 – 21 July 2019

Venue: Putra World Trade Centre (PWTC), Kuala Lumpur,Malaysia

Booth No: 2020 & 2021, Hall 2