| What if an aerospace O-rings is not properly tested for cycle of extreme cold & Heat (Thermal shock)? In history, That cold rubber became stiff, failing to fully seal the joint and caused the NASA’s space shuttle Challenger tragedy that killed seven astronauts on Jan. 28, 1986

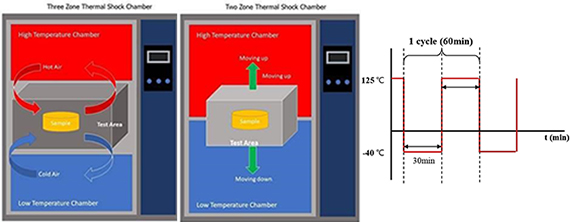

Thermal shock refers to fluctuation in temperature which causes stress in a material. Often, it results in fracture, crack, bend, etc especially to brittle materials such as ceramics. Thermal Shock simulation test is exposing a test sample through high temperature and low temperature in a continuous cycle rapidly. And is usually applied to military products, aerospace ,automotive, packaging, or electronics to verify its ability to adapt and find out will it affect the product physically, characteristically, or it functionality MERIDIAN Thermal Shock Simulation Test Structures Need equipment or advice on Thermal Shock Simulation Test?Reach out to our expert today for a professional recommendation. Mr. Yap Hon Loon, Product Specialist, +6012 -3925901, [email protected] Mr. Eddie Ridzwan Lee, Product Specialist, +6012-213 5901, [email protected] You can browse our list of Thermal Shock View original post here |