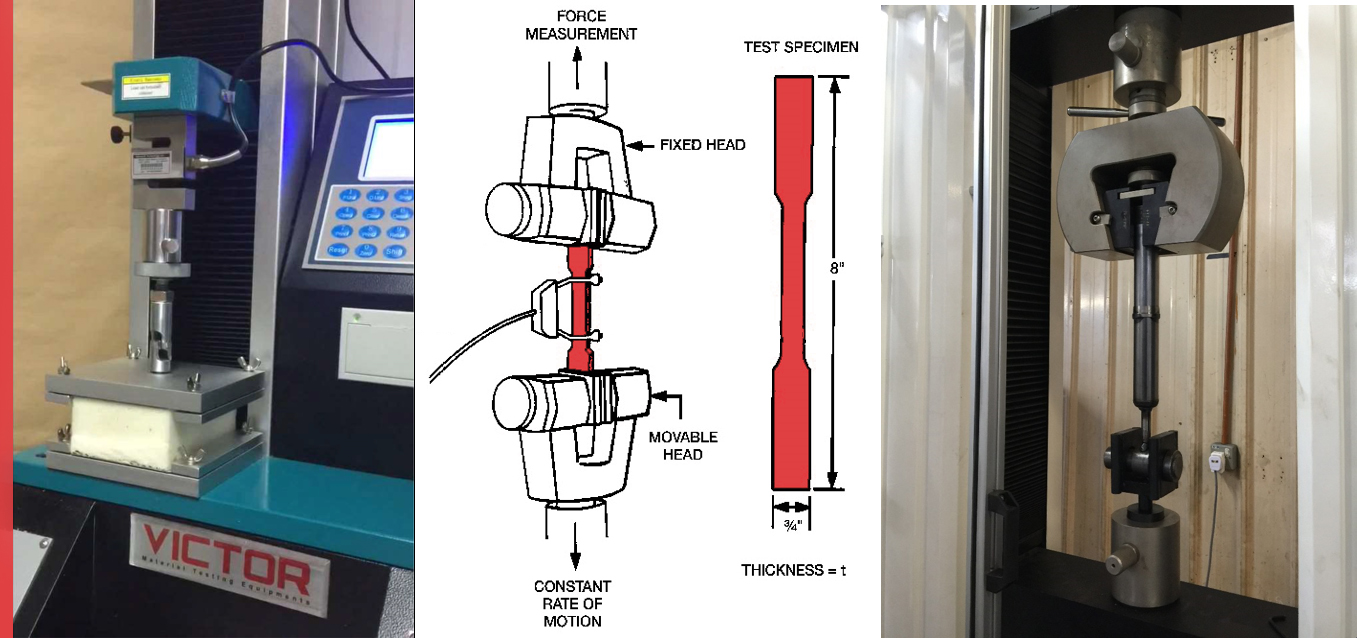

Tensile testing is one of the simplest and most widely used mechanical tests to determine how the test sample will react when it is pulled apart aka to discover its breaking point when an external force/stress is applied onto it.

This allows product designers and quality managers to analyse their material properties and predict how their materials and products will behave in their intended applications.

Examples of raw material samples from rubber, metal, foam, textile, and plastic for tensile testing.

BENEFITS

The tensile test helps by ensuring manufacturers to :

- Achieve lean manufacturing goals (to improve the quality of products, eliminate unnecessary waste, reduce production times and reduce total costs)

- Ensure the integrity and safety of materials, components, and product

- Aid in the design process

- Ensure compliance with international and industry standards

- Ensure product consistency in its highest quality

INDUSTRY APPLICATION

- Aerospace & Automotive

- Food, Beverage, Packaging, Paper and Card Board

- Construction & Steel

- Electrical and Electronics

- Pharmaceuticals

- Plastics, Rubber, and Elastomers

- Safety

- Textiles and much more!

Customised Grips, Jigs & Fixtures

Did you know that we can customised your tensile test experience with the right attachments?

View our customised attachments gallery from our manufacturing website.

NEED THE RIGHT TENSILE TEST ACCESSORIES /EQUIPMENT? REFER TO :

Alvin George, Product Specialist (+6012-2232593)

[email protected] cc [email protected]

Browse our list of Material Testing Equipment via www.victormaterial.com and for our Services at www.victortestingmachine.com