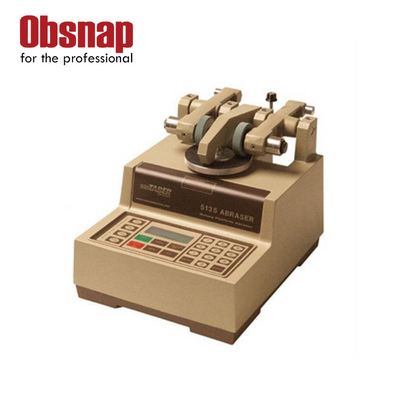

TQC sheen – Abrasion Testers – Taber Abraser

Taber Abrasion is used to determine relative resistance to abrasion defined as ‘the ability of a material to withstand mechanical damage’ such as rubbing, scraping or erosion.

The Taber Abraser is an industry standard used in the wear and durability testing of parquet, metals, leather, textiles, rubber, lacquered surfaces, carpets, coatings etc..

Single or dual versions available. A wide range of accessories and options is available.

Taber Abrasers Model 5135 or 5155 offer the following standard features:

-

Specimen turntable speed control options of both 60 rpm and 72 rpm.

-

Easy-to-use operator interface that includes tactile feel buttons and a four line digital display. Simple on-screen instructions allow the operator to change the test parameters via the MENU button. An internal memory stores the settings.

-

A vacuum system is included and is critical for the proper operation of the instrument. The vacuum nozzle(s) is hinged to an adjustable mounting at the rear of the housing. A precision vacuum nozzle adjustment control allows the height to be modified for accommodating varying specimen thickness.

-

Stainless steel weights are furnished to provide standard wheel loads of 500 or 1000 grams. Weights are actually 250 or 750 grams, but are marked to show total load on each wheel. This marking includes the weight of the abrading arm (250 grams).

-

A Quick Release Mounting Hub permits quick wheel mounting without the need of a locking nut, increased clearance for the vacuum pick-up nozzle and a larger viewing area for the test specimen. A beveled retaining nut provides a positive locking force on the wheel hub retaining lip making certain that the wheels remain securely fastened until disengaged.

-

Assembled in a sturdy, sealed aluminum housing.