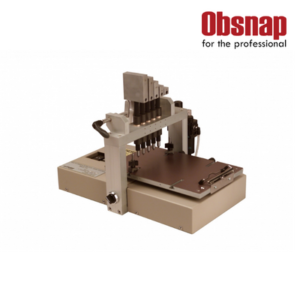

TQC sheen – Abrasion Testers – Taber Reciprocating Abraser

The test tool mentioned in test method ISO 1518 is identical to the TABER® Reciprocating Abraser (Abrader) – Model 5900. This tester, which works best for flat surfaces, can be set up with optional attachments to assess the relative susceptibility or resistance of a material surface to physical damage, including wear and abrasion, rub, scratch, mar, gouge, and scrape, among others.

Description

The Taber Reciprocating Abraser has a counterbalanced arm that pivots on a gantry system with changeable height. Regardless of the weight of the attachment, the counterweight enables the user to balance the test arm and ensure exact test load setup. A tool holder with space for optional attachments and weights is built into the end of the arm. Under the stationary tool holder, a sliding specimen platform reciprocates in a horizontal motion.

It is possible to vary test parameters such as stroke length (6-155mm), speed (3-75 cycles per minute), and load (1N-24N maximum, with weights of 1N, 2N, 2.5N, 5N, 10N & 24N provided) in order to find the best settings for each material.

Optional auxiliary weights are offered separately and come in weights of 50g, 100g, 150g, 200g, 500g, 1000g, 2000g, 2400g, and 5000g to increase test loads. Additionally, the top of the tool holder may be attached with an extra weight support. This enables the use of additional weight discs created for Taber’s Linear Abraser 5750. (10g, 20g, 50g, 75g, 100g, 150g or 250g).

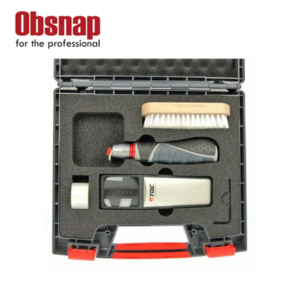

Each Taber Reciprocating Abraser includes a Wearaser® collet assembly as well as CS-10 and H-18 Wearaser abradants as standard equipment. The Wearaser, which is made of the same premium Taber abrasive media as our Genuine Taber abrading wheels, is the size and shape of a pencil eraser. This enables the Reciprocating Abraser, Taber’s Linear Abraser, and Taber Rotary Platform Abraser to all be used with comparable abrasives.

The Reciprocating Abraser comes with a standard specimen table that is 216mm x 278mm (8.5′′ x 11′′) and has been drilled and tapped to accept specimen clamps or additional specimen fastening plates. Specimen clamps or the optional Wide Slot Fixing Plate may be appropriate for testing the majority of flat specimens. Use of the supplementary Specimen Fixing Plate Kit may be appropriate for flexible materials like textile items. The included specimen clamps or a custom fixture can also be used to hold products with a slight curve in place.

Up to three tests can be run at once using the Reciprocating Abraser’s capacity for two extra test arm kits (sold separately).

Evaluation

Due to the wide variety of test attachments that can be used with the TABER Reciprocating Abraser (Abrader), there is no universal method to interpret results. The two most common methods include:

Cycles to a Specific End-Point – The number of cycles required to reach a predetermined end point, or the appearance or condition of the specimen after a fixed number of cycles. The evaluation criteria may include: loss in coating, change in gloss, color loss, or other changes in appearance. In these cases, the abraded sample is usually compared to a known standard of the material tested. When visually inspecting changes in specimen appearance, evaluations should be made using an agreed upon rating system such as a visual grading scale (e.g. five-step) or pass/fail criteria.

Weight (Mass) Loss – This technique measures how much material has been removed by abrasion, and is usually reported in milligrams.

L = A – B

where L = weight loss

A = weight (mass) of specimen before abrasion

B = weight (mass) of specimen after abrasion

Related products

Paint Strength Testers

Paint Strength Testers

TQC sheen – Abrasion Testers – Taber Multi-Finger Scratch Mar Tester

Paint Strength Testers

TQC sheen – Bending / Impact / Cupping Testers – Manual Cupping Test

Paint Strength Testers

TQC sheen – Hardness / Scratch Resistance Testers – Buchholz Hardness Indentation Test