Mahr Metrology MarForm MFU 200 Aspheric 3D

With the MarForm MFU 200 Aspheric 3D , you can inspect optical components quickly and close to production in 2D and 3D. MarForm measuring machines have been known for their accuracy and stability for decades.

With the MarForm MFU 200 Aspheric 3D, you have a high-precision measuring instrument at your disposal that, with its very small measurement uncertainty, is ideally suited to the requirements of your process optimization.

By using the measuring station in a vibration-damped cabin, external interference such as vibrations and dirt are kept away from the measuring objects.

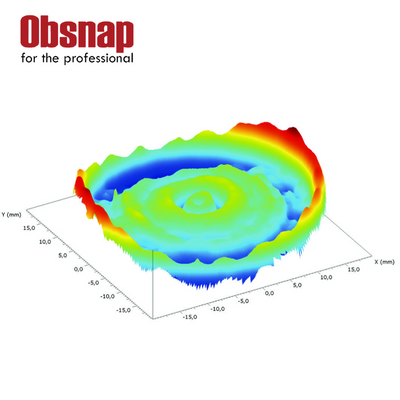

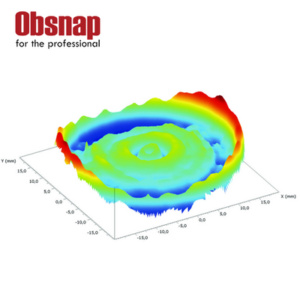

Optical and tactile sensors can be positioned in any angular position (0° to 360°) via a motorized swivel joint and thus offer a high degree of flexibility. The RMS value, PV value and the gradient error are displayed as parameters.

In the software, the individual parameters for the aspheres such as the radius of curvature R0, the conical constant k and the aspheric coefficients Ai can be adjusted to the measurement results when adapting the target asphere to the fit asphere.