HV-FLY Series Bridge CMMs

Machine Overview:

FLY series CNC three-coordinate measuring machine is high-precision flexible measuring equipment, and capable of completing any measurement and detection task rapidly and effectively. It can meet much measuring needs by matching various scanning and trigger probes, so that to be a concise, rapid and efficient measuring system with high precision.

Feature:

- The integral granite workbench make the machine characterized with the good rigidity, strong bearing capacity, wide workpiece placing space and convenient loading and unloading; The main guide rail is designed to be longer to increase the span of guiding air bearing, and substantially improve the guiding precision of the main guide rail;

- The elevated structural style is adopted by the Y-direction main guide rail, so that the inertia of the moving parts is reduced, the transmission parts are closer to the center of inertia, and even if the measuring machine with big specification is provided, its good motion characteristics and precision stability can also be guaranteed;

- The longest axis use high precision tooth-shape driving, which guarantee rather good transmission rigidity; the rest 2 axis adopt high performance synchronous belts, which is not only to get rather fast motion velocity to increase measuring efficiency, but also to reduce transmission inertia to the uttermost to improve the motion acceleration;

- Z-axis adopts the adjustable pneumatic balance device , which can adjust the counterbalance with facility although equipped with different probe systems, so that it can reach the best state.

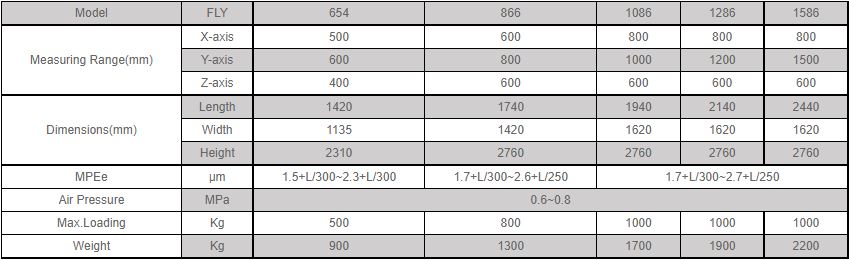

Tech Specs :

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice. (2020-05)

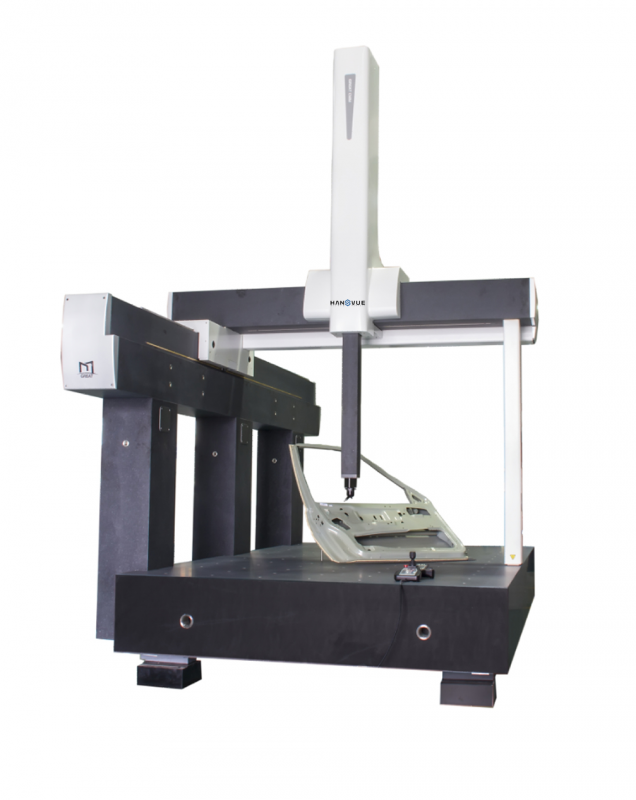

HV-EXPERT Series High-Accuracy Bridge CMMs

Machine Overview

The classical mobile bridge structure possesses the broad feeding and discharging space. The self adaption metallic frictional transmission system with patent technology effectively improves the dynamic performance of measuring machine especially be suitable for application of scanning and measuring system.

Feature

- The tri-axle is adopted with rectangular guide rail with elaborated design, and the so-called various “Unique “and “Patented” and even strange polygon guide rail structures are abandoned , returning to nature. The correction model upon rectangular guide rail error is simple and practical; the form is most common form in the high-precision measuring machine.

- Long axis is adopted with the most ideal three-coordinate transmission system recognized by industry currently—- metallic frictional transmission. Compared with such gear-shape transmission as common synchronous belt and gear rack, the tooth profile efficiency is eliminated completely to enable that the trans-mission is more steady, effectively eliminate the machine shock brought by the flexible telescoping of synchronous belt and improve the transmission rigidity of measuring machine so as to reach better starting, stopping and positioning capability, which is ideal selection for high-precision scanning measurement.

- The surrounding-type air bearing layout design is adopted uniformly for tri-axle, and the pre-compression air bearing with high air membrane rigidity is utilized. Through comparison between with other layout and surrounding layout on all sides, the pre-compression force for each air bearing may realize the individual control and non-interference mutually to enable that each air bearing can work under most ideal status.

- Two columns of measuring machine are adopted with double layer design fully to lower the influence on measuring machine precision by external temperature change and air conditioner’s air supply system to enable that the measuring machine is provided with more powerful environment adaptability.

- The brand-new pedestal design of measuring machine is completely compatible with high-efficient passive vibration isolation system or positive air vibration isolation system to meet the utilization demand of plant with strong earthquake source and on-line measurement.

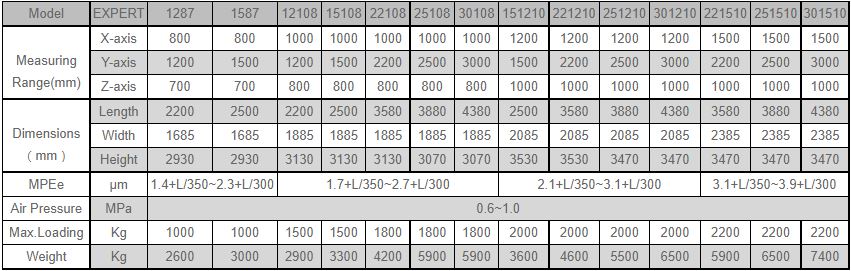

Tech Specs :

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice.(2020-05)

HV-GREAT Series Single-Side Bridge CMMs

Machine overview:

GREAT series is specially designed for the of wide-range workpiece inspection, and its unilateral elevated structure has high dynamics and stability, thus, comprehensively meeting the requirements of measurement and quality verification from automobile manufacturing, large mold and precision spare parts.

Features

- The integral granite workbench make the machine characterized with the good rigidity, strong bearing capacity, wide workpiece placing space and convenient loading and unloading; The main guide rail is designed to be longer to increase the span of guiding air bearing, and substantially improve the guiding precision of the main guide rail;

- The elevated structural style is adopted by the Y-direction main guide rail, so that the inertia of the moving parts is reduced, the transmission parts are closer to the center of inertia, and even if the measuring machine with big specification is provided, its good motion characteristics and precision stability can also be guaranteed;

- The longest axis use high precision tooth-shape driving, which guarantee rather good transmission rigidity; the rest 2 axis adopt high performance synchronous belts, which is not only to get rather fast motion velocity to increase measuring efficiency, but also to reduce transmission inertia to the uttermost to improve the motion acceleration;

- Z-axis adopts the adjustable pneumatic balance device , which can adjust the counterbalance with facility although equipped with different probe systems, so that it can reach the best state.

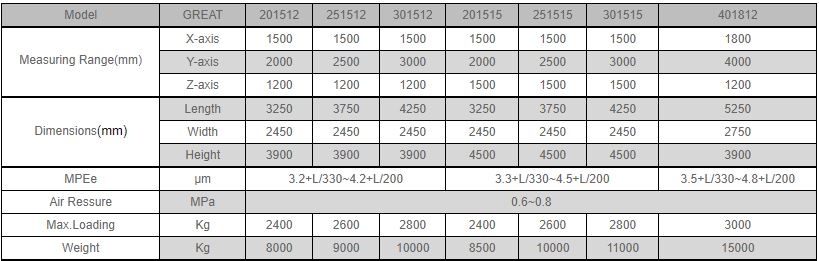

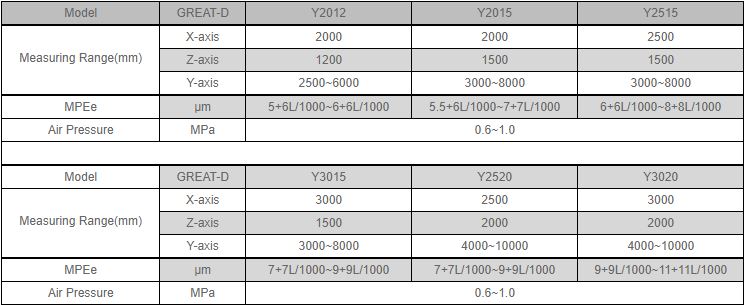

Tech Specs :

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice.(2020-05)

HV-GREAT-D Series Gantry CMMs

Machine Overview:

GREAT-D series measuring machine is designed for ultra-large workpiece measurement, and its open-type gantry structure has high dynamics and stability, floor-type design meet the need for larger measuring range parts, which may obtain more flexible moving space and facilitate loading, unloading and measurement for large-size and heavy workpiece.

Feature:

- The open-type landing gantry structure is available, so as to facilitate the loading and unloading and measurement of the large-size and heavy workpiece. The dual optical scales system can be arranged, thereby, further improving the precision and stability of the machine.

- All guide rails use the high-precision & rigidity air bearing, and the rigidity and stability of the machine are improved by means of the encircling guide rail type layout design, so that the high precision can also be maintained even if working for a long time, and meanwhile, the excellent dynamic characteristics of the machine are ensured.

- Three-axis guide rail are made of high-quality granite, which could keep the same temperature characteristics, and then, have good temperature stability and anti-aging deformation ability, good rigidity and minimum geometry deformation.

- The application of non-linear spring reduces the influence of minor error of the slide way towards the measuring precision, meanwhile it also guarantees machine’s higher adaptability to the environmental temperature.

- Z-axis’s torsion plays a critical role in the precision of a CMM. Its reliable anti- torsion structure design also can achieve a high precision in the case of using probe extension bar. Z-axis adopts the adjustable pneumatic balance device , which can adjust the counterbalance with facility although equipped with different probe systems, so that it can reach the best state..

- The imported high-precision air filter on the machine can assure the ultra high cleanliness of the compressed air, so that could effectively protecting the air bearing and guide rail, meanwhile, the automatic drainage device makes operators economical with time and effort, avoiding the possible harm to the machine caused by man-made negligence.

Tech Specs

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice.(2020-05)

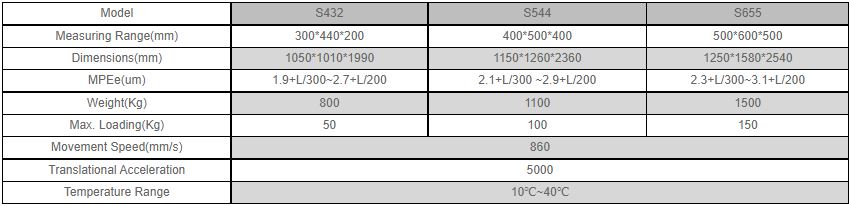

HV-SMART Series Ultra High Speed Shop-Floor CMMs

Machine overview:

SMART series of super-high -speed CMM have the characteristics of wide temperature range, powerful measuring function, stable performance, high precision, simple operation, fast and efficient, easy maintenance characteristics. It adopts high precision linear guide technology, uses ultra-high speed linear motor drive, with multiple workpieces and environmental temperature sensor, is a super high speed, high precision, no air source CMM used in the condition of wide temperature, Especially suitable for workshop environment, and can also be used as the comprehensive test station of workshop.

Technology and function description:

- Wide temperature range, can be used in 10℃ ~ 40℃ environment.

- Ultra- high speed measurement and acceleration ability is 3 times of ordinary CMM.

- Turn on and use, no isothermal process is required.

- Dustproof design, can be used in the production workshop.

- No air source design, do not need compressed air, power can be used.

- Support automatic interface to realize intelligent online measurement.

- Four – way feeding, convenient in automatic production line layout.

- The integrated design of the whole machine takes up little space and saves precious production line space.

- Easy to move, use forklift can be easily moved to any position.

- Simple operation, support drag-and-drop operation, support the workshop special software interface.

Workshop special version software

1.Intelligent production line integration.

The software supports data interface which can obtain measurement program measurement from the server, or send measurement results to MES system or other data servers.

2.Scan code measurement

The software also supports the use of a scanning gun or RFID scanner to initiate the specified measurement procedure. Measurement software supports a variety of expansion modules, according to customer requirements for selection.

3.Manual measurement

Users only need to add the workpiece to the measured workpiece as required, and then click the measurement engineering icon corresponding to the measured workpiece to complete the automatic measurement of the workpiece.

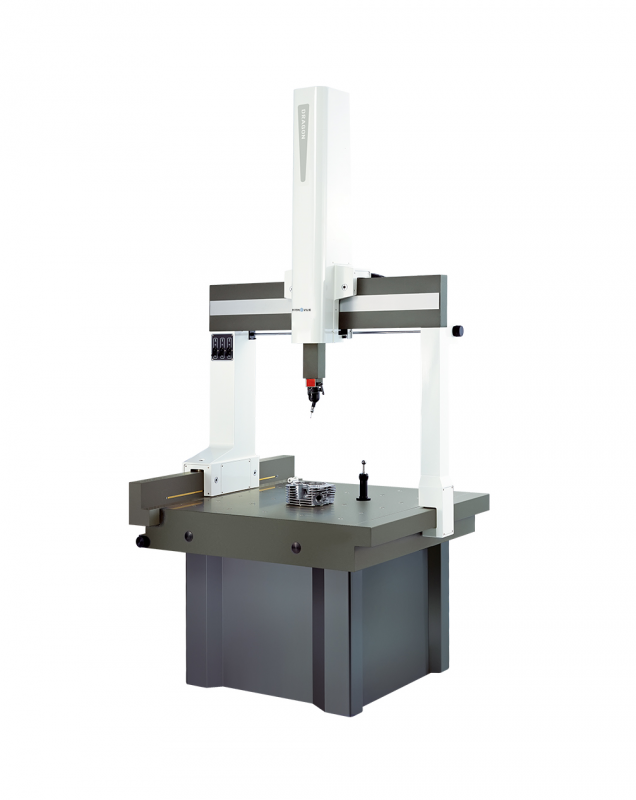

Tech Specs

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice.(2020-05)

HV-DRAGON Series Manual CMMs

Machine Overview:

Easy & reliable in operation The manual operation mode easy to learn can meet the diversified accurate measurement requirements of the workshop site.

Features:

- When operating the manual measuring machine, the operator only hold the probe by hand to move it along X, Y and Z axis, so as to complete the whole measurement process. Manual measuring machine use the fixed workbench with good rigid structure and light weight, and fully enclosed frame moving bridge structure, which can carry strong capacity and obtain good motion performance.

- Manual machine has better quality rigidity ratio, and optical video system is optional to choose to meet the various different inspection requirements at workshop.

- The gantry-moving structure, integral workbench make the machine have strong bearing capacity wide workpiece placing space and convenient loading and unloading.

- The high-precision air bearing is used, and the rigidity and stability of the machine are improved by means of the encircling bearing layout design, so that the high precision can also be maintained even if working for a long time, and meanwhile, the excellent dynamic characteristics of the machine are ensured.

- 3 axis’s fast moving, locking& fine tuning could be realized through only 1 key . With tightly flipping the switch corresponding to air locking device, each axis will be shifted from fasting moving to locking condition. Fine tuning switch could be used to moving X, Y, Z axis after locking, This function is fully embodied especially when inspecting those narrow parts of the workpiece.

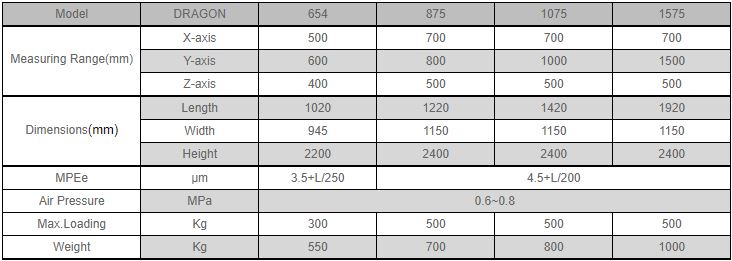

Tech specs

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice.(2020-05)

HV-TOP Series Ultra High Accuracy Fixed Bridge CMMs

Machine overview:

The TOP series adopt the fixed bridge structure, the high accuracy high efficiency organic union in together. It can realize high speed scanning and rapid data collection. The measuring machine is especially suitable for precision measurement in the whole 3D measuring technology, especially in quality system, research and development, and calibration of measuring tools and gauges.

Feature:

- The measuring machine is designed with fixed bridge and movable table. Its structure has the advantages of high rigidity, good precision stability and strong resistance to external interference, The high inertia moving shaft adopts the high rigid transmission mode, which can reach the high motion acceleration even when measuring the large workpiece.

- The vibration isolation design of transmission mechanism can reduce the influence of mechanical vibration on measuring accuracy when the machine moves at high speed.

- The three-axis drive system is close to the mass center, which reduces the inertia yaw and ensures the stability of the motion even in the high acceleration state.

- The grating system is close to the measured workpiece, which can effectively reduce Abbe error.

- The three-axis guide rails are all made of high quality granite, so that the three-axis guides have the same temperature characteristics, good temperature stability, effective deformation resistance, good rigidity and small dynamic geometric error deformation.

- All the guides rails are designed with closed structure to improve the rigidity and stability of the machine. Even if the machine works for a long time, it can maintain high precision and ensure excellent dynamic characteristics of the machine. Three axis guide rail adopts self – cleaning loading high precision air bearing, the movement is more stable.

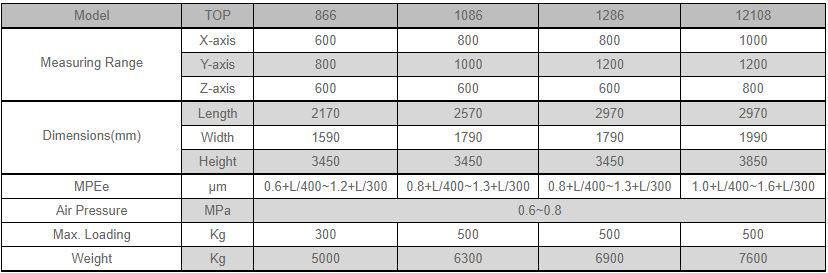

Tech specs

Note: The accuracy of the machine of the same specification caries according to the configuration. The technical parameters and appearance of the product during the execution of this version of the sample may be updated without prior notice. (2020-05)