SPECTRUM: BRIDGE TYPE CMM

Machine Overview:

With the ZEISS SPECTRUM coordinate measuring machine you will enter a new level of precision and trusted results – at an unmatched price performance ratio.

Feature:

ZEISS Coordinate Measuring Machine . Model: Spectrum

Distinctive features:

– Ceramic guides for maximum stability

– Unbeatable price vs. performance ratio

Accuracy MPE E0: (1.9 + L/250)µm

Sizes:

5/5/6, 7/7/6, 7/10/6, 10/12/6 and 10/16/6

Software: Calypso

Sensor (probe system):

XDT or RDS VAST XXT

Sensor (Probe System)

XDT

Sensor (Probe System)

RDS VAST XXT

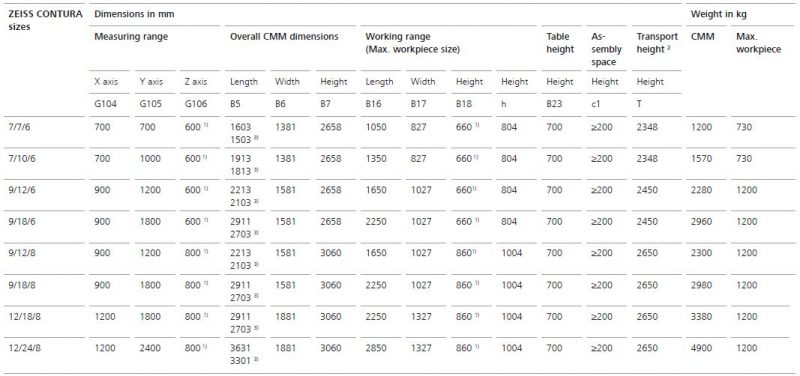

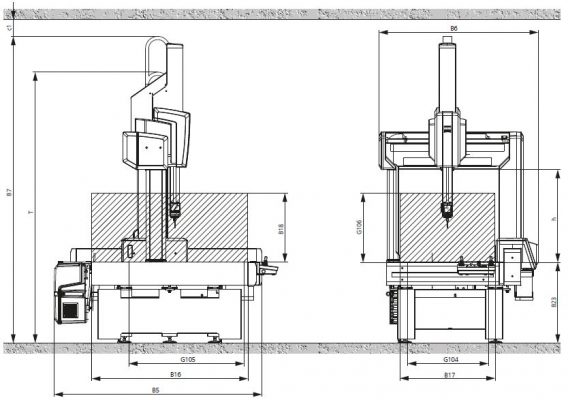

CONTURA: BRIDGE TYPE CMM

Machine Overview

ZEISS CONTURA comprises an extensive range of sensors and thus offers the right sensor or sensor system for every application and every requirement. With the mass technology, a large number of ZEISS sensors can be operated with high precision and quickly replaced on the same measuring instrument: Sensors with an articulating probe holder or fixed probe configuration, optical or tactile, passive or active – this is how ZEISS CONTURA achieves maximum flexibility.

Feature and Tech Specs

ZEISS Coordinate Measuring Machine Model: Contura

Distinctive features:

– New generation CMM prepared for Industry 4.0

– Maximum flexibility with MASS technology; exchange-able sensors, easily

Accuracy MPE E0: (1.7 + L/350)µm

Sizes:

7/7/6, 7/10/6, 9/12/8, 9/18/8 12/18/8 and 12/24/8

Software: Calypso

Sensor (probing system):

XDT, RDS VAST XXT, VAST XT, DotScan, LineScan and ViScan

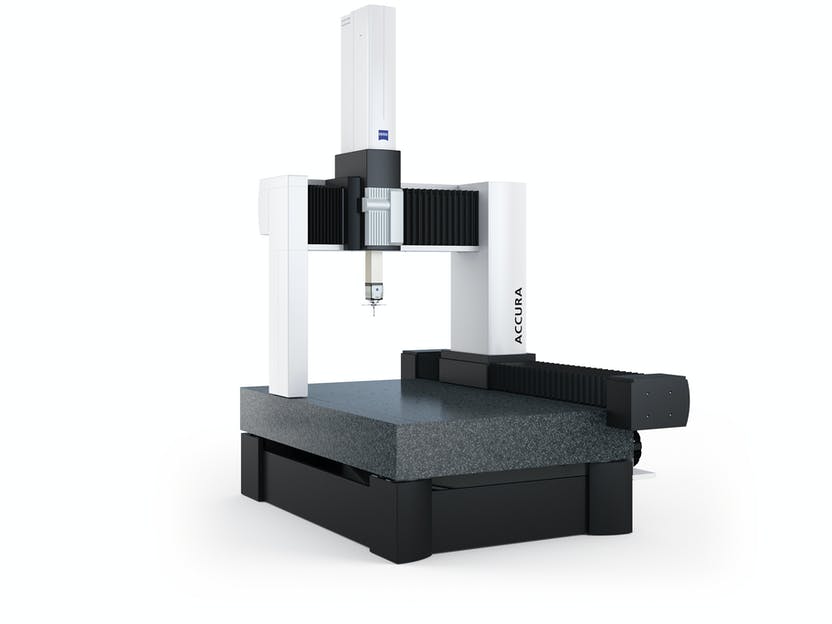

ACCURA: BRIDGE TYPE CMM

Machine overview:

With its wide range of configurations, the ZEISS ACCURA measuring machine can be tailored to your needs – and budget.

Features and Tech specs

ZEISS Coordinate Measuring Machine. Model: Accura

Distinctive features:

– Larger CMM, light-weighted and high dynamic

– Comes standard with Navigator for faster calibration, approach and scanning

Accuracy MPE E0: (1.6 + L/350)µm

Sizes:

9/12/8 – 9/16/8, 12/18/8 – 12/42/10, 16/24/10 – 16/42/10, 16/24/15 – 16/42/15 and 20/24/15 – 20/42/15

Software: Calypso

Sensor (probing system):

XDT, RDS VAST XXT, VAST XT, DotScan, LineScan and ViScan

Sensor (Probing System)

XDT

Sensor (Probing System)

DotScan

Sensor (Probing System)

RDS VAST XXT

Sensor (Probing System)

LineScan

Sensor (Probing System)

VAST XT

Sensor (Probing System)

ViScan

PRISMO: BRIDGE TYPE CMM (HIGH ACCURACY)

Machine Overview:

PRISMO from ZEISS is a reference in precision measurement and follows the ISO quality standards entirely. An essential in a world where precision matters the most and compromises on accuracy are not acceptable.

Feature and Tech Specs

ZEISS Coordinate Measuring Machine .Model: Prismo | Prismo Ultra

Distinctive features:

– High accuracy and high speed scanning

– Available option with operating temperature up to 40°C, accuracy guaranteed

Accuracy MPE E0: (0.9 + L/350)µm | (0.5 + L/500)µm

Sizes:

From 7/9/5 to 16/42/10

Software: Calypso

Sensor (probing system):

XDT, RDS VAST XXT, VAST XT, DotScan, LineScan, ViScan and Rotos

Sensor (Probing System)

XDT

Sensor (Probing System)

DotScan

Sensor (Probing System)

Rotos

Sensor (Probing System)

RDS VAST XXT

Sensor (Probing System)

LineScan

Sensor (Probing System)

VAST XT

Sensor (Probing System)

ViScan

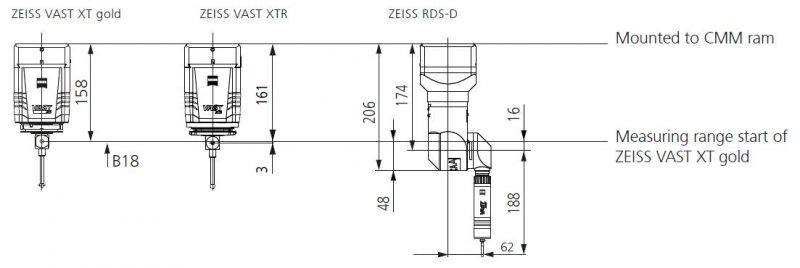

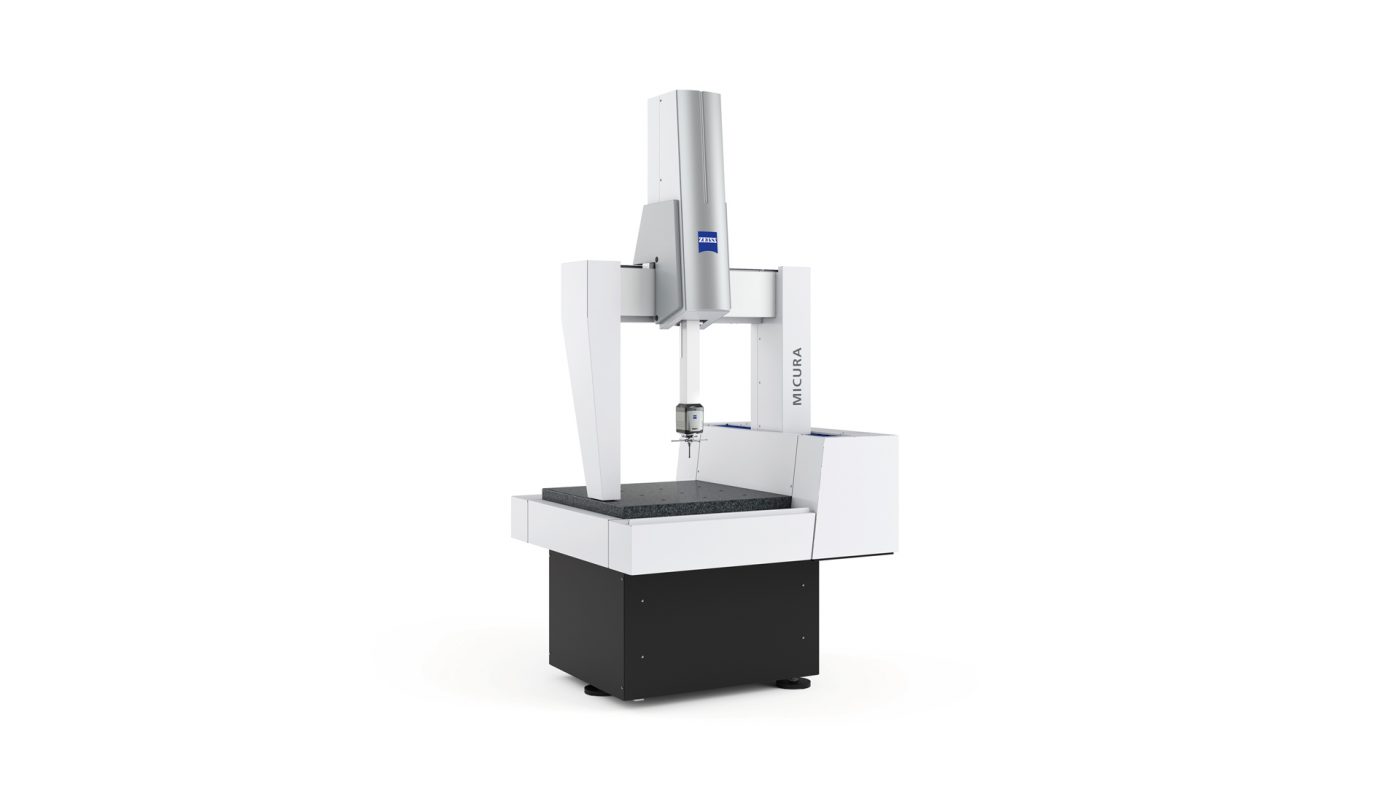

MICURA: BRIDGE TYPE CMM (HIGH ACCURACY)

Machine overview:

ZEISS MICURA is the solution for new demands in industrial production where parts are becoming increasingly compact and accuracy requirements are rising.

Despite its small size, ZEISS MICURA makes no compromises when it comes to accuracy. ZEISS MICURA comes standard with the VAST XT gold scanning sensor from ZEISS and navigator technology.

Features and Tech Specs

ZEISS Coordinate Measuring Machine Model: Micura

Distinctive features:

– Small CMM for smaller parts with higher accuracy

– Comes standard with VAST XT Gold or VAST XTR Gold

Accuracy MPE E0: (0.7 + L/400)µm

Sizes:

5/5/5 and 5/7/5

Software: Calypso

Sensor (probing system):

VAST XT Gold or VAST XTR Gold

Sensor (Probing System)

VAST XT

Sensor (Probing System)

VAST XT GOLD

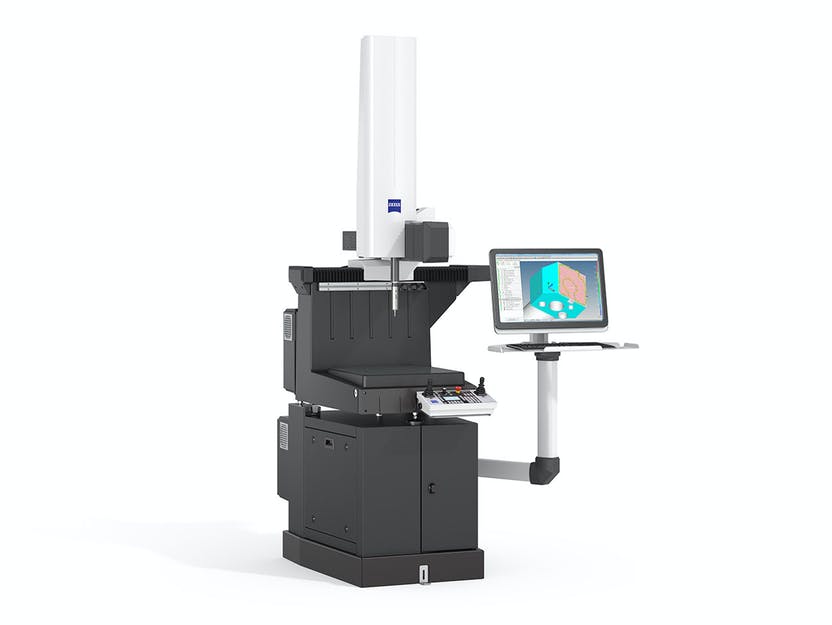

DURAMAX: PRODUCTION CMM

Machine Overview:

ZEISS DuraMax eliminates the need for fixed gauges. Equipped with the VAST XXT scanning sensor from ZEISS, it can even be used to capture contours and freeform surfaces.

Features and Tech Specs

ZEISS Coordinate Measuring Machine Model: Duramax

Distinctive features:

– Compact footprint, enclosed guideways, need no compressed air; a true shopfloor CMM

– Open areas for easy-part-loading, maximum utilization of measuring range

Accuracy MPE E0: (2.4 + L/300)µm

Sizes:

5/5/5

Software: Calypso

Sensor (probing system):

VAST XXT

Sensor (Probing System)

VAST XXT

PRO T: HORIZONTAL ARM CMM

Machine overview:

The ZEISS PRO T is a modular horizontal arm measuring machine that is very easy to configure. This means that it can be ideally tailored to meet your cost efficiency and performance requirements.

Feature:

ZEISS Horizontal Arm Coordinate Measuring Machine. Model: Pro T

Distinctive features:

– Modular design to suit specific measuring tasks, especially for car body or larger parts

– Continuous CSC articulating probe holder for maximum flexibility

Accuracy MPE E0 2D: From (25 + L/100)µm ≤ 60µm

Sizes:

From (XY) 12/25

Software: Calypso

Sensor (probing system):

CSC, EagleEye and RDS

Sensor (Probing System)

CSC

Sensor (Probing System)

EagleEye

Sensor (Probing System)

RDS

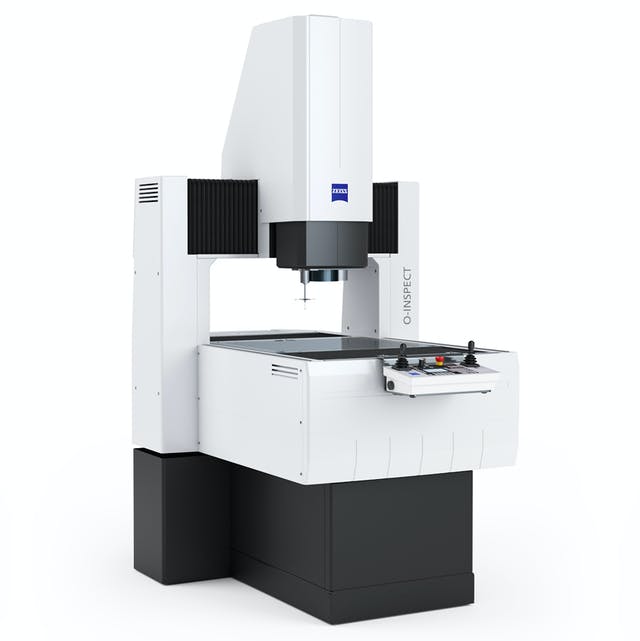

O INSPECT: MULTI-SENSOR CMM

Machine Overview

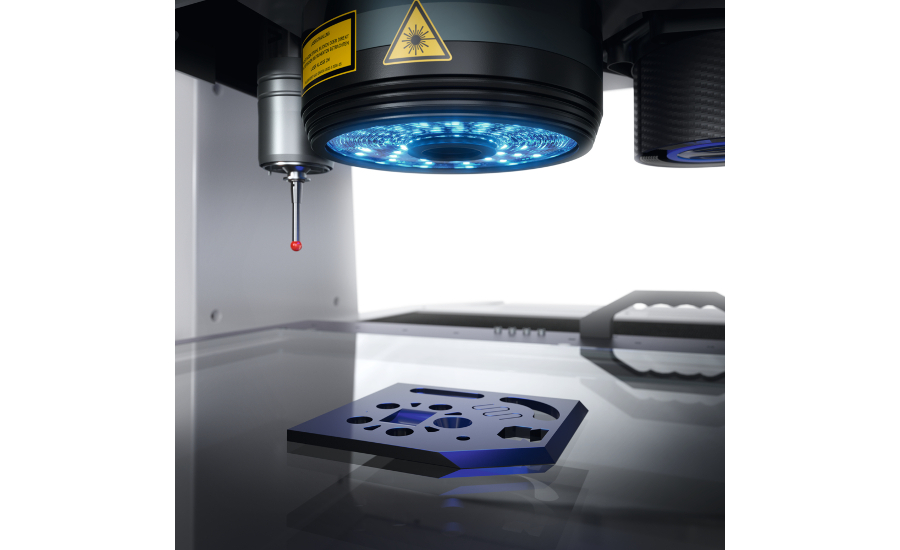

ZEISS O-INSPECT multi-sensor measuring machines enable to optimally measure each characteristic in compliance with ISO-10360 – optically or by contact.

Your advantages:

- Large visual field with high image definition

- Quick and precise 3D tactile measurements

- Optical measurements for sensitive surfaces

- Increased reliability in less time

Features and Tech Specs

ZEISS Multi-Sensor Coordinate Measuring Machine Model: O Inspect

Distinctive features:

– Perfect combination of Zeiss tactile technology and Zeiss Vision Discovery V12

– Additional sensor of DotScan and accessories of rotary axis, measurement possibilities almost infinity

Accuracy MPE E0 2D: (1.7 + L/250)µm

3D: (1.9 + L/250)µm

Sizes:

3/2/2, 5/4/3 and 8/6/3

Software: Calypso

Sensor (probing system):

V12, VAST XXT, Dotscan

Sensor (Probing System)

V12

Sensor (Probing System)

VAST XXT

Sensor (Probing System)

DotScan

XENOS: HIGHEST ACCURACY CMM

Machine overview

ZEISS XENOS is at home wherever maximum precision is demanded – in the measuring labs of research institutes, the aerospace industry and the optical industry. The high-end machine combines precision at the limits of what is technically feasible with a measuring range of nearly one cubic meter.

Features and Tech Specs

ZEISS Coordinate Measuring Machine. Model: Xenos

Distinctive features:

– Highest accuracy CMM possibly made in metrology world, known as The Reference

– Uses linear drives in all axes, machine structure parts relevant to accuracy made by silicon-carbide ceramic

Accuracy MPE E0: (0.3 + L/1000)µm

Sizes:

9/15/7

Software: Calypso

Sensor (probing system):

VAST XTR GOLD

Sensor (probing system):

VAST XTR GOLD