Description

The HI88713 Precision ISO Turbidity Benchtop Meter is specifically made for measuring the turbidity of water, and it delivers dependable results even at low turbidity levels. The instrument’s optical system is state-of-the-art, ensuring accuracy, long-term stability, and reducing stray light and color interferences. Any changes in the tungsten lamp’s intensity are offset by routine calibration using the provided standards. The repeatability of turbidity measurements is ensured by the 25 mm round cuvettes made of superior optical glass.

Features at-a-glance:

Four Measurement Modes – The HI88713 features four options for turbidity measurement: FNU (Formazin Nephelometric Units), FAU (Formazin Attenuation Units), and NTU (Nephelometric Turbidity Units) ratio and non-ratio mode. Turbidity ranges for each mode are 0.00 to 1000 FNU, 10.0 to 4000 FAU, 0.00 to 4000 NTU (ratio mode), and 0.00 to 1000 NTU (non-ratio mode).

Multiple Turbidity Units of Measure – Turbidity can be read as Formazin Nephelometric Units (FNU), Formazin Attenuation Units (FAU), European Brewing Convention units (EBC), and Nephelometric Turbidity Units (NTU).

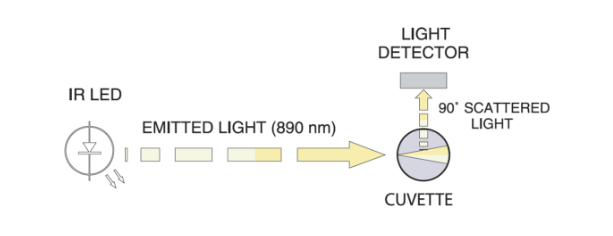

ISO Compliant – The HI88713 meets and exceeds the requirements of ISO 7027 method for turbidity measurements by use of an infrared LED light source.

Calibration – The HI88713 has a powerful calibration function that compensates for variation in light intensity. The calibration can be done using the supplied calibration solutions or user-prepared standards. A two, three, four, or five-point turbidity calibration can be performed by using the supplied (<0.10, 15, 100, 750 FNU, and 2000 NTU) standards. Calibration points can be modified if user-prepared standards are used.

AMCO AEPA-1 Primary Turbidity Standard – The AMCO AEPA-1 supplied standards are recognized as a primary standard by the USEPA. These non-toxic standards are made of styrene divinylbenzene polymer spheres that are uniform in size and density. The standards are reusable and stable with a long shelf life.

GLP Data – The HI88713 features complete GLP (Good Laboratory Practice) functions that allow traceability of the calibration conditions. Data includes calibration points, date, and time.

Data Logging – Up to 200 measurements can be stored in the internal memory and recalled at any time.

Data Transfer – For further storage or analysis options, logged data can be downloaded to a Windows compatible PC using the USB port and the HI92000 software.

Tutorial Mode – The unique tutorial mode provides additional information to help the user during measurements. When enabled, the instrument displays explanations and a confirmation button when a preparation or other operation has to be performed.

Contextual Help – Contextual help is always available through a dedicated HELP button. Clear tutorial messages and directions are available on-screen to quickly and easily guide users through setup and calibration. The help information displayed is relative to the setting/option being viewed.

Backlit Graphic LCD Display – A graphic LCD display provides an easy to understand, user-friendly interface. All messages are in plain text making them easy to read.

Measurement of diffuse radiation for water with low turbidity (0 FNU to 40 FNU)

- The wavelength of the incident radiation shall be 860 nm

- The spectral bandwidth of the incident radiation shall be less than or equal to 60 nm

- There shall be no divergence from parallelism of the incident radiation and any convergence shall not exceed 1.5o.

- The measuring angle, theta, between the optical axis of the incident radiation and that of the diffused radiation shall be 90o +/- 2.5o.

- The aperture angle should be between 20o and 30o in the water sample.

Measurement of attenuation of radiant flux for highly turbidity (40 FAU to 4000 FAU)

- The wavelength of the incident radiation shall be 860 nm

- The spectral bandwidth of the incident radiation shall be less than or equal to 60 nm

- There shall be no divergence from parallelism of the incident radiation and any convergence shall not exceed 2.5o.

- The measuring angle of the incident radiation and that of the diffuse radiation shall be 0o +/- 2.5o.

- The aperture angle should be between 10o and 20o in the water sample.

The HI88713 meets and exceeds the meter criteria specied by ISO 7027.

Principal of Operation

The HI88713-11 AMCO AEPA-1 standards ensure that measurements are traceable to a primary reference materials. These standards are used for calibration and performance verification of the turbidity meter.

Supplied with Certificate of Analysis

- Lot number

- Expiration date

- Standard value @ 25 °C

- Reference meter NIST traceable

Provided storage containers

- Light tight

- Protects from accidental breakage

| SKU | HI88713-02 |

|---|---|

| Product Name | ISO 7027 Compliant Benchtop Turbidity Meter – HI88713 |

| Quote Required | Yes |

| Turbidity Range | FNU mode |

| Turbidity Resolution | FNU mode |

| Turbidity Accuracy | FNU mode |

| Turbidity Repeatability | ±1% of reading or 0.02 NTU (0.15 Nephelos; 0.01 EBC) whichever is greater |

| Turbidity Stray Light | < 0.02 NTU (0.15 Nephelos; 0.01 EBC) |

| Turbidity Calibration | two, three, four, or five-point calibration |

| Turbidity Measuring Method | nephelometric method (90°) or ratio nephelometric method (90° & 180°), adaptation of the USEPA Method 180.1 and Standard Method 2130 B |

| Turbidity Measuring Modes | normal, average, continuous |

| Turbidity Light Source | IR LED |

| Turbidity Light Detector | silicon photocell |

| Logging Memory | 200 records |

| Connectivity | USB |

| Display | 40 x 70 mm graphic LCD (64 x 128 pixels) with backlight |

| Power Supply | 12 VDC adapter (included) |

| Environment | 0 to 50°C (32 to 122°F), RH max 95% non-condensing |

| Dimensions | 230 x 200 x 145 mm (9.0 x 7.9 x 5.7”) |

| Weight | 2.5 kg (88 oz.) |

| Ordering Information | HI88713 is supplied with sample cuvettes and caps (6), calibration cuvettes, silicone oil, cuvette wiping cloth, power adapter, and instruction manual. |