3D Scanning Services

Our 3D Scanning Services deliver precise digital models of physical objects using advanced technology. Ideal for reverse engineering, quality inspection, and product development, we capture complex geometries with high accuracy to support efficient design and manufacturing.

3D Scanning Services Available

1. Reverse Engineering, 3D Inspection, 3D Printing & Finite Element Analysis (FEA)

2. 3D Scanning & Probing Measurement Services

3. 3D Scanning for Human Body

4. 3D Scanning for Art Sculpturing & Wood Carving

5. 3D Probing for High Precision First Article Inspection (FAI)

6. 3D Probing for Jigs & Fixture Inspection

Details For 3D Scanning Services Available

Reverse Engineering, 3D Inspection, Printing & FEA

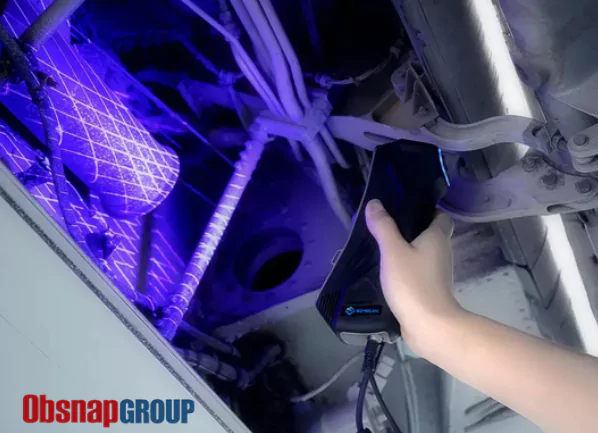

Obsnap offers reverse engineering and 3D scanning solutions for digital reconstruction, part validation, and CAD modeling. Using advanced Scantech scanners, CMM arms, and software like Geomagic Design X and SolidWorks, we deliver accurate CAD-ready files for applications such as legacy part modeling, fit analysis, redesign, and rapid prototyping.

3D Scanning & Probing Measurement Services

Obsnap’s hybrid metrology service combines 3D scanning and touch-probing for fast, precise dimensional data. Using Scantech TrackScan/SIMSCAN and Nikon MCAx systems with PolyWorks and Control X, we deliver full GD&T inspection up to ±0.03 mm accuracy for QA, automotive and aerospace validation, and complex surface analysis.

3D Scanning for Human Body

Obsnap offers fast, non-contact 3D body scanning that captures full-body data in under 60 seconds. The scans produce precise 3D mesh files (OBJ, STL, PLY) for healthcare, apparel, fitness, and virtual design applications such as prosthetics, virtual fitting, avatars, and posture analysis for all with GDPR-compliant data security.

3D Scanning for Art Sculpturing & Wood Carving

Obsnap provides precise 3D scanning for artists, museums, and restoration experts to digitize and preserve detailed artworks. We deliver accurate 3D models (STL, OBJ, mesh) with high-resolution textures for editing, printing, or rendering, ideal for sculpture replication, restoration, mold-making, CNC reproduction, and digital archiving of cultural heritage.

3D Probing for High Precision First Article Inspection (FAI)

Obsnap delivers high-precision First Article Inspection (FAI) using certified probing systems to ensure production parts meet design and specification standards. We provide geometric tolerance analysis, deviation mapping, and detailed GD&T reports with pass/fail results, ideal for aerospace, automotive, and defense validation, as well as supplier qualification and ISO compliance.

3D Probing for Jigs & Fixture Inspection

Obsnap provides precise inspection of jigs, fixtures, and tooling using 3D probing to verify dimensional accuracy and alignment. We perform hole and dowel checks, flatness and geometry analysis, and CAD-based fit validation, ideal for tooling setup, maintenance, and quality assurance in automotive, aerospace, and precision manufacturing.