Description

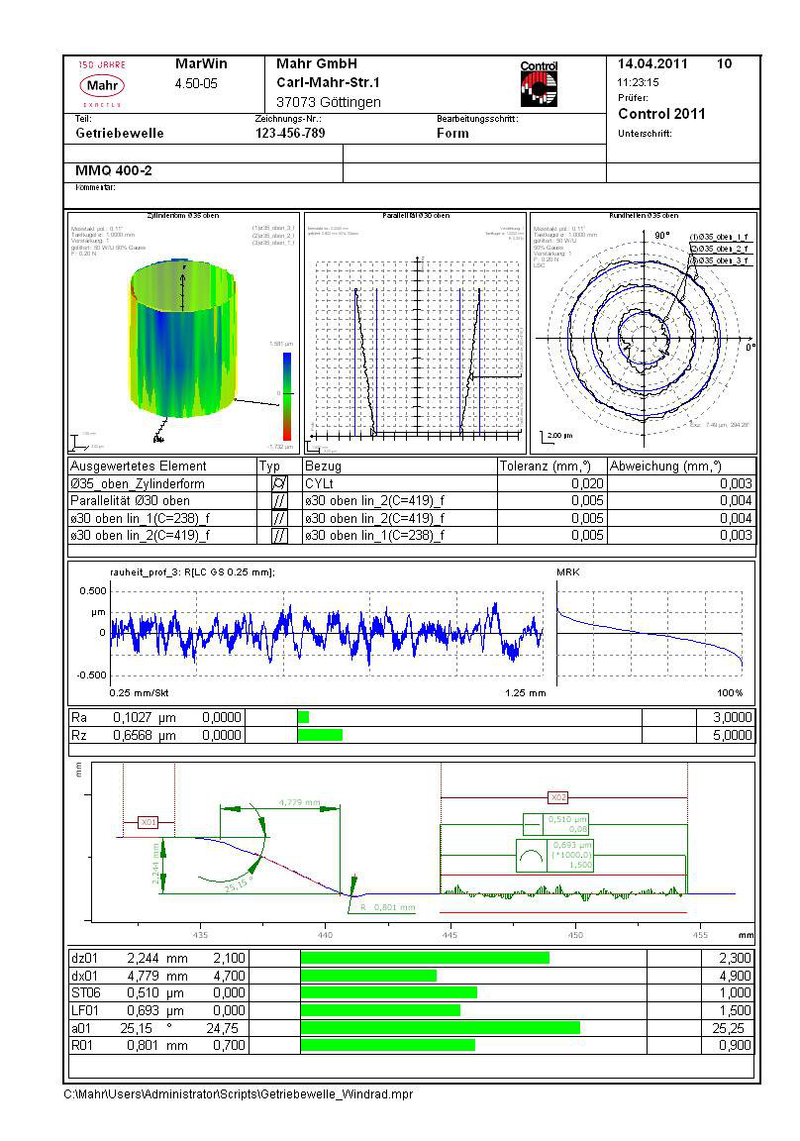

| MarForm MMQ 400 | Art.-Nr. 5440787 | |

|---|---|

| Roundness deviation (µm+µm/mm measuring height) * | 0,01 + 0,00025 |

| Measuring path, motorized Z (mm) | 900 |

| Straightness deviation / 100 mm measuring path (µm)**, Z axis | 0.15 |

| Straightness deviation / total measuring path (µm)**, Z axis | 0.9 |

| Parallelism deviation Z-/C axis in tracing direction, measuring path (µm) | 2 |

| Measuring speed (mm/s), Z axis | 0,1-30 |

| Positioning speed (mm/s), Z axis | 0,5 -100 |

| Measuring path, motorized X (mm) | 280 |

| Roundness deviation (µm+µm/mm measuring height) ** | 0,02 + 0,0005 |

| Straightness deviation /av. 100 mm measuring path (µm)**, X axis | 0.5 |

| Straightness deviation / total measuring path (µm)**, X axis | 1.5 |

| Axial runout deviation (µm+µm/mm measuring radius) * | 0,02 + 0,0001 |

| Axial runout deviation (µm+µm/mm measuring radius) ** | 0,04 + 0,0002 |

| Centering and tilting table | automatic |

| Table diameter (mm) | 285 |

| Table load capacity, centered (N) | 400 |

| Speed (rpm) 50 Hz / 60 Hz | 0.2-15 |

| Footer text | * Values as maximum deviation from LSC reference circle, filter 15 undulations/revolution. ** All values in accordance with DIN ISO 1101 at 20°C ±1°C in a vibration-neutral environment, filter 15 undulations/revolution LSC or 2.5 mm LSS, 5 rpm or 5 mm/s and standard probe arm with ball diameter 3 mm. Proof at the standard using error separation techniques. Given the number of different options available, only a few machines are described here by way of example. Technical data for “your” MMQ is available from Mahr on request. |