Our Services

Home / Services

Factory Automation Equipment

Smarter Automation. Seamless Production.

How Can We Help You?

Factory Automation Equipment

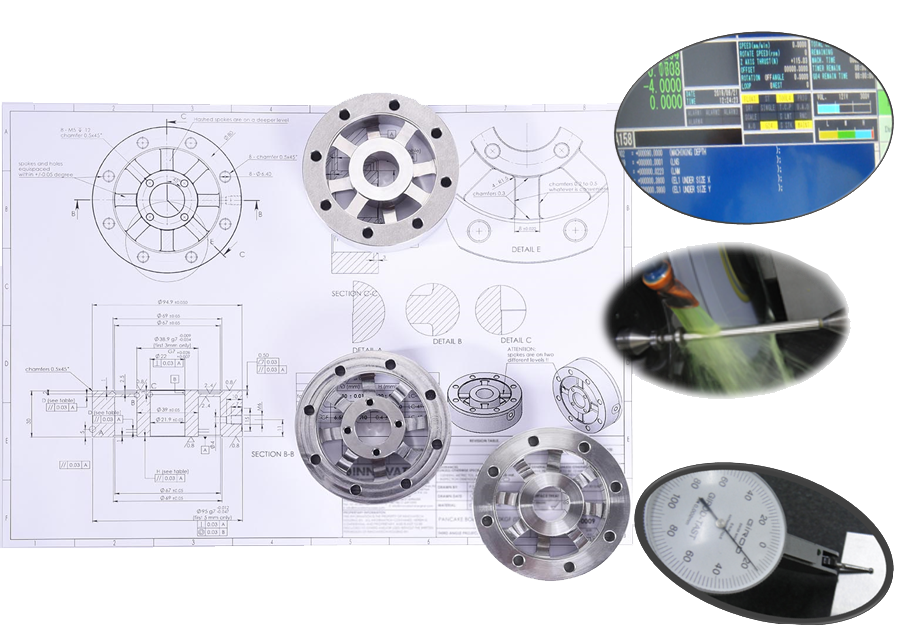

From precision motion control to intelligent sensors and robotic systems, Obsnap offers a wide range of factory automation equipment designed to streamline operations, reduce downtime, and boost productivity. Our solutions integrate seamlessly into diverse manufacturing environments helping you achieve faster, safer, and more consistent production output while maintaining top-tier quality standards.

Revolutionize Your Workflow: Obsnap’s Factory Automation in Action

Discover how Obsnap’s factory automation equipment transforms production lines with speed, precision, and intelligence. From robotic arms to smart sensors, see our solutions in action and learn how they optimize manufacturing processes across industries.

Find the Equipment That Powers Your Production Goals

Explore Obsnap’s specialized range of factory automation equipment engineered for performance, reliability, and integration. From precision motion systems to intelligent control units, discover solutions that enhance efficiency, ensure consistent output, and drive innovation across diverse manufacturing environments.

Assembly Systems

Assembly Systems automate precise component assembly with vision inspection options, defect prevention, and efficient PC-based control.

Inspection Systems

Inspection Systems automate defect detection, classification, and mapping with high-precision inspection and calibration for reliable quality control.

Marking Systems

Marking Systems provide automated, precise code and barcode marking with mapping and calibration for wafers, lead frames, and substrates.

Assembly Systems

Assembly Systems automate precise component assembly with vision inspection options, defect prevention, and efficient PC-based control.

Inspection Systems

Inspection Systems automate defect detection, classification, and mapping with high-precision inspection and calibration for reliable quality control.

Marking Systems

Marking Systems provide automated, precise code and barcode marking with mapping and calibration for wafers, lead frames, and substrates.

Testing Systems

Testing Systems automate functional testing, inspection, and sorting with precision handling and efficient control.

Jigs & Fixtures

Jigs & Fixtures are specialized tools designed to support testing and evaluation of PCBs, battery chargers, bearings, and other components, ensuring accuracy, reliability, and defect detection.

Testing Systems

Testing Systems automate functional testing, inspection, and sorting with precision handling and efficient control.

Jigs & Fixtures

Jigs & Fixtures are specialized tools designed to support testing and evaluation of PCBs, battery chargers, bearings, and other components, ensuring accuracy, reliability, and defect detection.

Real Solutions. Real Industrial Impact.

At Obsnap Group, we provide cutting-edge factory automation equipment that drives measurable improvements in manufacturing performance. Our case studies showcase real-world success stories where our automation solutions have helped clients optimize production lines, reduce downtime, and achieve greater efficiency and consistency across various industrial sectors.

Case Study 1: Large-Volume Laser Scanning for Aerospace Assembly

Product: AXE-B11 handheld 3D laser scanner

Challenge: It was difficult to quickly digitize large aerospace structures while maintaining scan accuracy.

Solution: With the AXE-B11, operators leveraged its dual-mode laser system, high-speed capture (1.3 M points/second), and photogrammetry integration to scan large volumes with 0.020 mm/m accuracy .

Outcome: Accelerated assembly verification, reduced manual measurement time, and enabled seamless integration of large-scale parts.

Case Study 2: Reliable Concrete Compression Testing

Industry

Civil Engineering & Construction

Challenge

A construction firm working on high-rise projects required accurate compression strength testing of concrete samples to comply with local building codes and ISO standards.

Solution

Obsnap provided the VU 2000F Compression Testing Machine and trained the client’s technicians on its use. The system was paired with automated data acquisition software to ensure traceable, real-time results.

Outcome

The client improved testing throughput by 30%, minimized manual errors, and passed regulatory inspections with zero non-conformities.

Case Study 3: Hygienic, Non-Destructive Quality Control

Industry

Food & Packaging

Challenge

A packaged snack company needed a solution to detect foreign metal particles in their production line without damaging packaging integrity.

Solution

Obsnap installed a Walk-through Metal Detector and Checkweigher System tailored for food-grade applications. These systems offered high sensitivity and integration with conveyor lines.

Outcome

Contamination risk was reduced by 95%, product recalls dropped to zero, and customer trust was reinforced.

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

You can explore our products by industry or testing type in the navigation menu. If you're unsure, our team can recommend equipment based on your testing needs and standards.

Yes. Our equipment is designed to meet global standards such as ISO, ASTM, and others. Specific compliance details are listed on each product page.

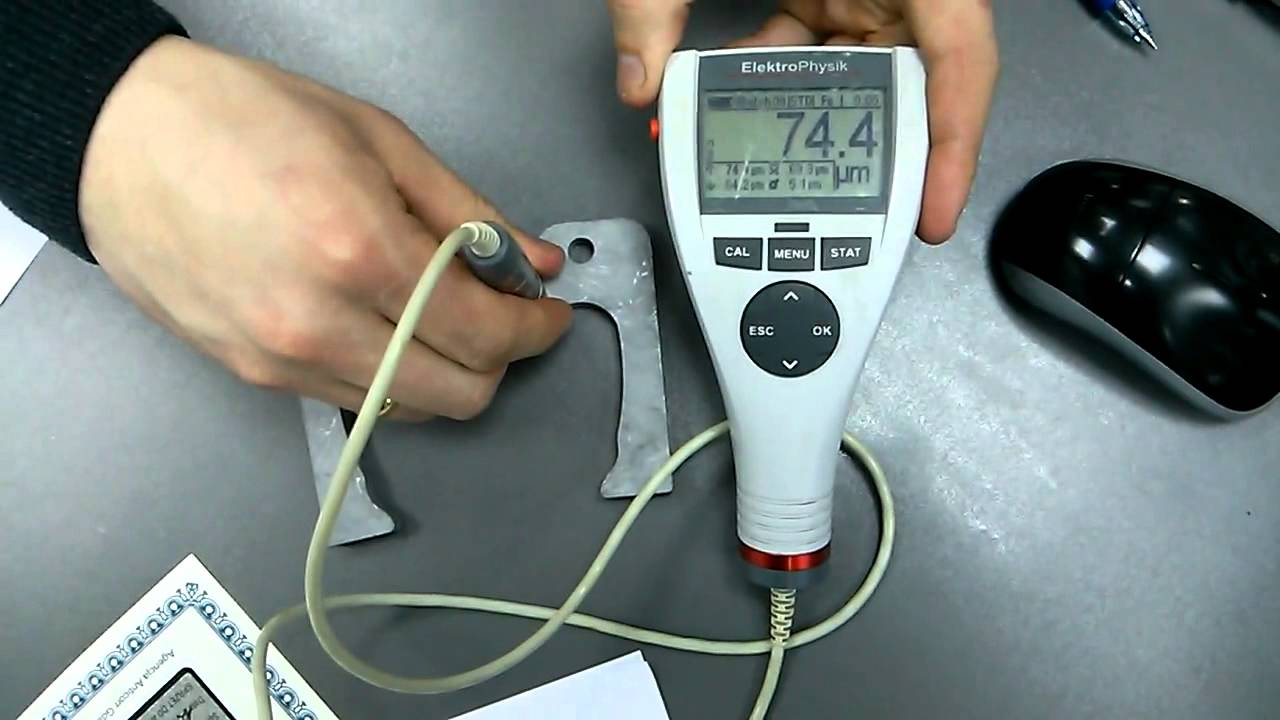

Yes, we provide calibration services for a wide range of testing and measuring instruments, both during purchase and as part of ongoing maintenance support.

Recalibration frequency depends on usage and industry standards. Our technical team can advise you on recommended intervals and provide scheduled calibration services.

Yes, rental services are available for selected instruments. Please contact us to check availability and rental terms.

We offer repair services, including diagnostics and part replacement. Contact our service department to arrange for evaluation.

We stock a variety of accessories and spare parts for most of our equipment. Reach out to our support team with your product model for assistance.

Driving Your Business Forward

By Testing Type

Testing & Measuring Instruments

Material Testing & Sample Preparation

Scientific Apparatus & Environmental Test

Detection / Analysis / Inspection

Factory Automation

Video Measurement System

3D Scanner

Portable CMM

Labelling Machine