Detection & Analysis Inspection

Uncovering Truth Through Precision – Detect, Analyze, Assure.

How Can We Help You?

Metal Detection & Elemental Analysis Inspection

The strategic partnership between Obsnap and JS Analytikal enables us to deliver more advanced inspection and analytical solutions for detecting defects, validating material integrity, and ensuring industry compliance. By combining expertise in flaw detection, surface inspection, and elemental analysis, this collaboration helps customers identify anomalies earlier, minimize operational risks, and maintain high-quality standards across manufacturing, construction, and research environments.

Precision in Every Scan: Detection & Analysis Inspection by Obsnap

Step into a new era of precision with Obsnap and JS Analytikal. Our Detection & Analysis Inspection solutions detect defects, verify material integrity, and provide accurate analytical insights across industries. From flaw detection to elemental analysis, we help you improve reliability, reduce risks, and ensure global compliance. With advanced handheld and integrated systems, make confident, data-driven decisions with clarity and precision.

Features of Metal Detection & Elemental Analysis Inspection

Versatile System Integration

Compatible with SMT/PCB, die-casting, and packaging inspection setups.

High Detection Accuracy

Identifies even the smallest metallic contaminants and material inconsistencies with precision.

Durable and Easy Maintenance

Built for long-term industrial use with dependable calibration and repair support.

Fast and Reliable Performance

Ensures quick inspection and calibration to maintain smooth production lines.

Compliance-Ready

Meets safety and quality standards required in food, manufacturing, and industrial sectors.

Advanced Imaging Technology

Utilizes X-ray and spectrometry systems for detailed internal and elemental analysis.

Application of Metal Detection & Elemental Analysis Inspection

Food and Beverage Industry

Detects metal contaminants to ensure product safety and regulatory compliance.

Electronics Manufacturing (SMT/PCB)

Inspects solder joints, components, and connections for quality assurance.

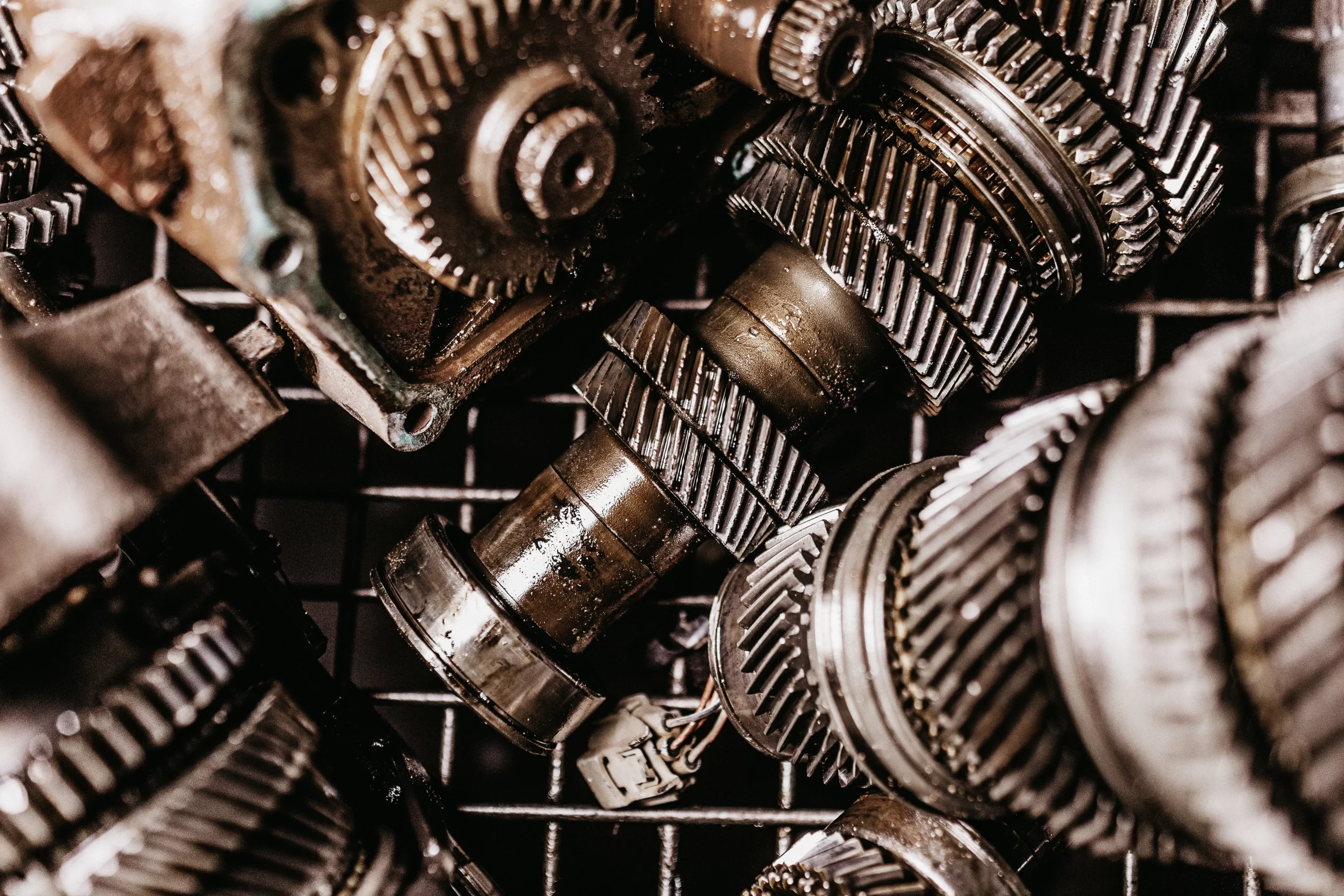

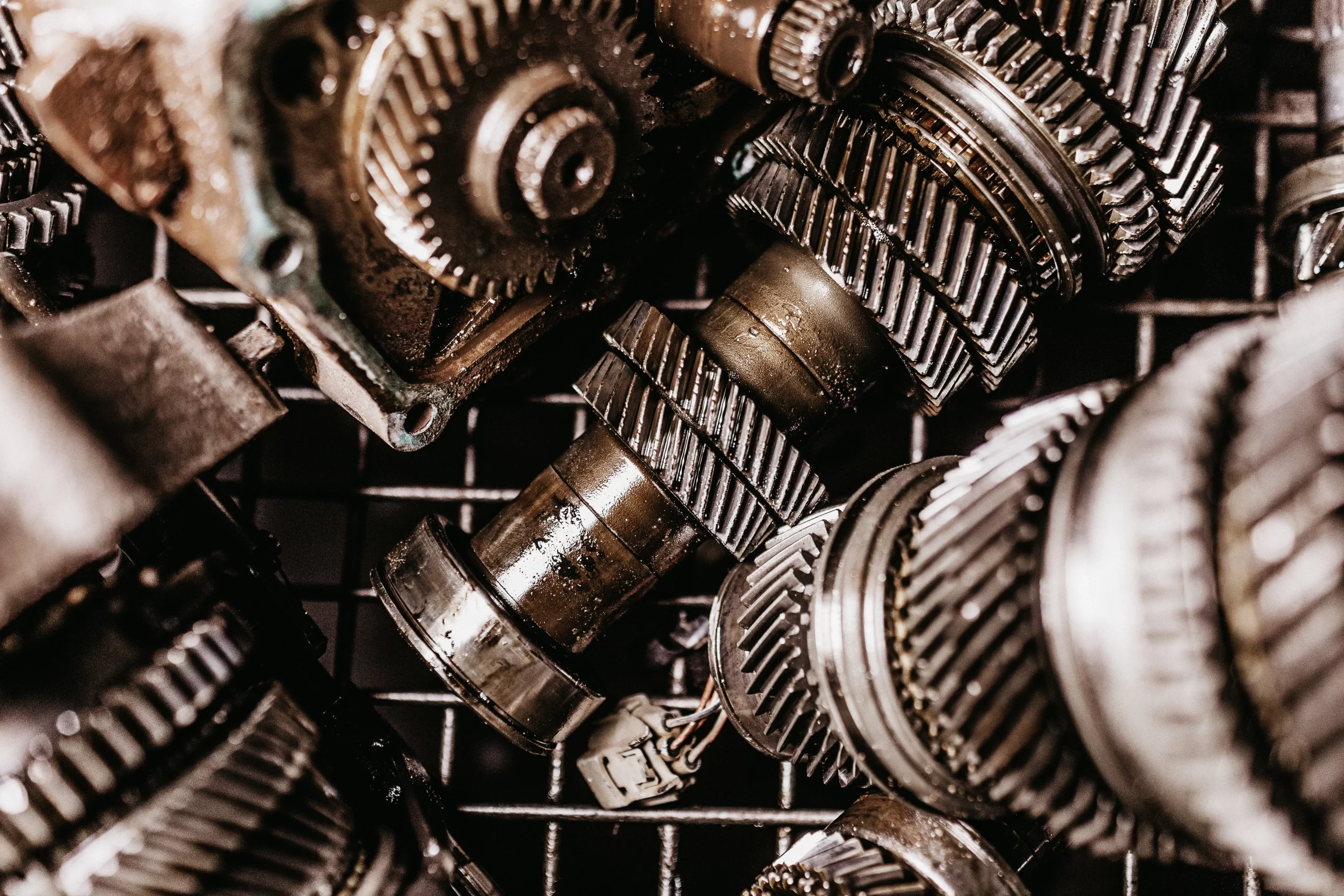

Die-Casting and Automotive Components

Verifies structural integrity and detects internal defects in metal parts.

Security and Screening

Used in walk-through metal detectors for identifying contraband in public or restricted areas.

Food and Beverage Industry

Detects metal contaminants to ensure product safety and regulatory compliance.

Electronics Manufacturing (SMT/PCB)

Inspects solder joints, components, and connections for quality assurance.

Die-Casting and Automotive Components

Verifies structural integrity and detects internal defects in metal parts.

Security and Screening

Used in walk-through metal detectors for identifying contraband in public or restricted areas.

Find the Series That's Right for You

Explore Obsnap’s specialized range of detection and analysis inspection instruments designed for precision, reliability, and critical insight. From portable testers to high-performance inspection systems, our solutions help you detect flaws, analyze materials, and ensure compliance across industries. Whether you’re inspecting for surface defects, internal inconsistencies, or elemental composition, find the right tools that elevate your quality control and decision-making process.

Metal Detector

We offer fast and reliable repair and calibration services for metal detectors in food and plastic industries, ensuring accurate detection, compliance, and smooth production with minimal downtime.

Elemental Analysis

Elemental analysis identifies the elements in a sample for accurate material verification. We supply reliable spectrometers and external-probe systems for precise testing across industries.

X-Ray Inspection (SMT/PCB)

X-Ray Inspection System is a technology that help to optimized high performance and super precision Die-casting exclusive Inspection system to optimize the applicable product size. We supply the best X ray Inspection System in Malaysia.

X-Ray Inspection (Diecasting)

X-Ray Inspection System is a technology that help to optimized high performance and super precision Die-casting exclusive Inspection system to optimize the applicable product size. We supply the best X ray Inspection System in Malaysia.

Walk-through Metal Detector

Walk-through metal detectors use Pulse Induction (PI) technology to detect metal objects as individuals pass through, generating rapid magnetic pulses through internal coils. These systems are designed to identify items such as knives, weapons, and other metal contraband, enhancing safety and security in public and restricted areas.

Metal Detector

We offer fast and reliable repair and calibration services for metal detectors in food and plastic industries, ensuring accurate detection, compliance, and smooth production with minimal downtime.

Elemental Analysis

Elemental analysis identifies the elements in a sample for accurate material verification. We supply reliable spectrometers and external-probe systems for precise testing across industries.

X-Ray Inspection (SMT/PCB)

X-Ray Inspection System is a technology that help to optimized high performance and super precision Die-casting exclusive Inspection system to optimize the applicable product size. We supply the best X ray Inspection System in Malaysia.

X-Ray Inspection (Diecasting)

X-Ray Inspection System is a technology that help to optimized high performance and super precision Die-casting exclusive Inspection system to optimize the applicable product size. We supply the best X ray Inspection System in Malaysia.

Walk-through Metal Detector

Walk-through metal detectors use Pulse Induction (PI) technology to detect metal objects as individuals pass through, generating rapid magnetic pulses through internal coils. These systems are designed to identify items such as knives, weapons, and other metal contraband, enhancing safety and security in public and restricted areas.

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

You can explore our products by industry or testing type in the navigation menu. If you're unsure, our team can recommend equipment based on your testing needs and standards.

Yes. Our equipment is designed to meet global standards such as ISO, ASTM, and others. Specific compliance details are listed on each product page.

Yes, we provide calibration services for a wide range of testing and measuring instruments, both during purchase and as part of ongoing maintenance support.

Recalibration frequency depends on usage and industry standards. Our technical team can advise you on recommended intervals and provide scheduled calibration services.

Yes, rental services are available for selected instruments. Please contact us to check availability and rental terms.

We offer repair services, including diagnostics and part replacement. Contact our service department to arrange for evaluation.

We stock a variety of accessories and spare parts for most of our equipment. Reach out to our support team with your product model for assistance.