When things aren’t working as they should

our technical team becomes the problem-solving partner that you can rely on. We investigate every detail, tracing issues to their true source so you’re not stuck with quick fixes that fail later. With the right tools, sharp expertise, and a methodical approach, we turn uncertainty into clarity and give you the confidence that your systems will keep running at their best.

Why Troubleshooting Matter

In industrial environments, downtime isn’t just inconvenient it’s costly. The bigger loss often comes from recurring problems that were never solved properly. Effective troubleshooting ensures:

Root-Cause Solutions

We go beyond quick fixes, using structured diagnostics to identify and resolve the actual source of the issue.

Increased Safety

Faults left unchecked can escalate into serious risks. Our process detects hidden hazards early, protecting both workers and machines.

Reduced Repeat Failures

On average, proper troubleshooting cuts recurring breakdowns by 30–50%, saving resources and preventing wasted effort.

Optimized Performance

Correctly diagnosed machines typically recover 90–100% of their original efficiency, ensuring smooth operations.

Long-Term Cost Savings

Eliminating misdiagnoses and unnecessary part replacements reduces both repair costs and unplanned downtime.

Industries We Serve

Troubleshooting is essential across industries where reliability and uptime are non-negotiable:

Manufacturing

Automotive

Electronics & Semiconductors

Manufacturing

Automotive

Food Processing

Heavy Industry

Hospitals

Energy & Utilities

Automotive

Heavy Industry

Hospitals

Energy & Utilities

Equipment Types We Handle

Our engineers are trained across multiple disciplines mechanical, electrical, automation, and control systems giving us the flexibility to troubleshoot a wide range of equipment:

Custom Industrial Equipment

Tailor-made machines with unique configurations that require flexible diagnostic approaches.

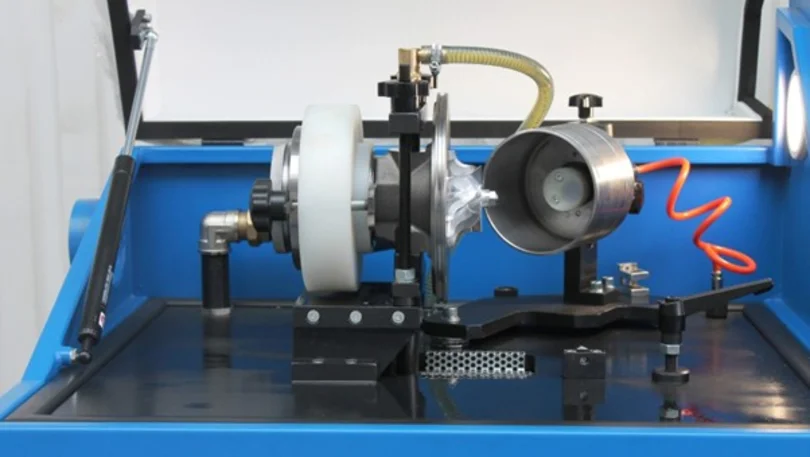

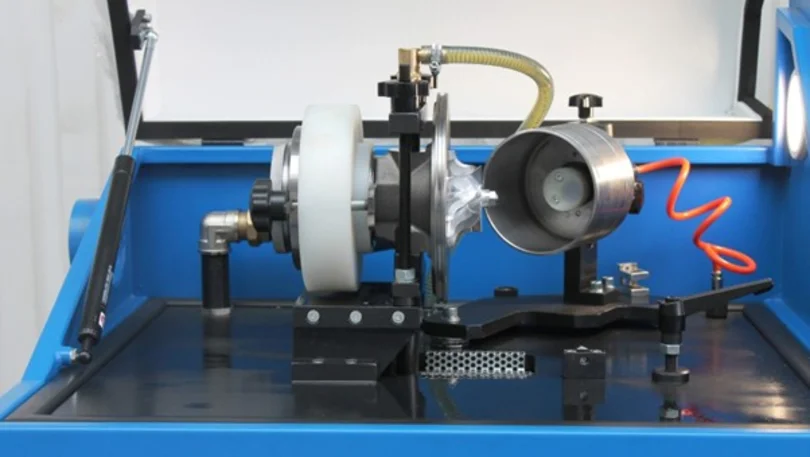

Turbocharger Balancing Machines

Identifying vibration, alignment, and calibration issues.

Hydraulic Presses & Testing Machines

Detecting hidden faults in hydraulic circuits, seals, and pressure systems.

Motors, Drives & Inverters

Troubleshooting failures in AC/DC motors, servo systems, and frequency drives.

Electronic Measurement Devices

Oscilloscopes, multimeters, spectrum analyzers, and specialized testers

PLC & Automation Systems

Diagnosing logic errors, wiring faults, and communication failures in automation networks.

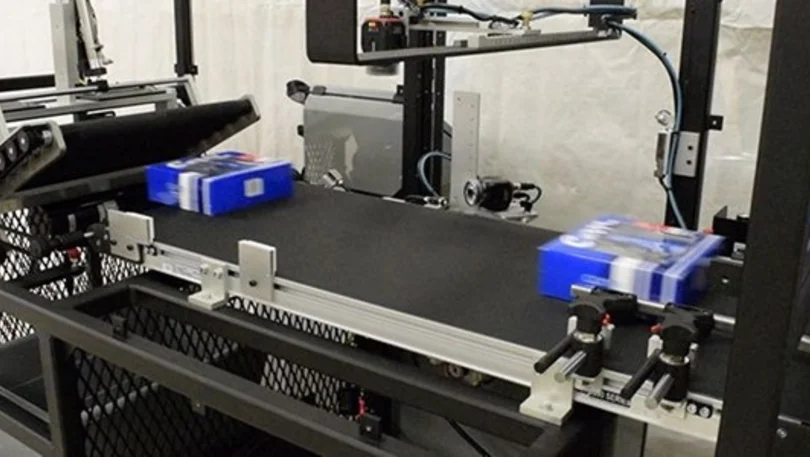

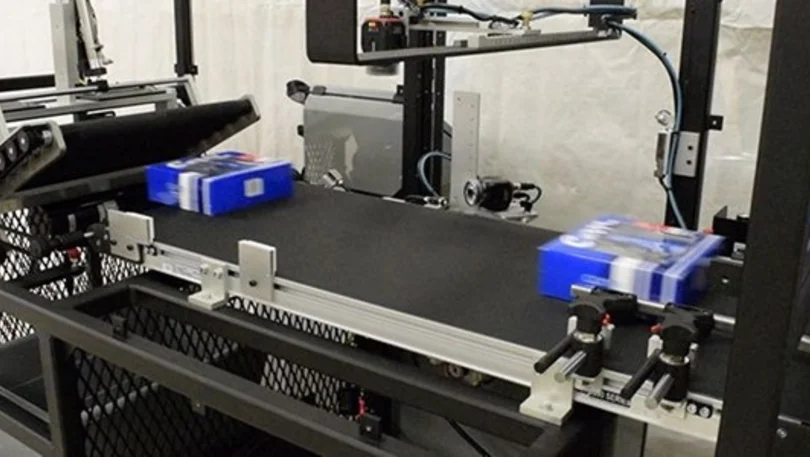

Automated Production Line Machinery

From conveyor belt systems to robotic arms, we pinpoint issues in integrated setups.

Calibration & Lab Equipment

Ensuring accuracy in hardness testers, tensile testers, and scientific instruments.

Custom Industrial Equipment

Tailor-made machines with unique configurations that require flexible diagnostic approaches.

Turbocharger Balancing Machines

Identifying vibration, alignment, and calibration issues.

Hydraulic Presses & Testing Machines

Detecting hidden faults in hydraulic circuits, seals, and pressure systems.

Motors, Drives & Inverters

Troubleshooting failures in AC/DC motors, servo systems, and frequency drives.

Electronic Measurement Devices

Oscilloscopes, multimeters, spectrum analyzers, and specialized testers

PLC & Automation Systems

Diagnosing logic errors, wiring faults, and communication failures in automation networks.

Automated Production Line Machinery

From conveyor belt systems to robotic arms, we pinpoint issues in integrated setups.

Calibration & Lab Equipment

Ensuring accuracy in hardness testers, tensile testers, and scientific instruments.

How It Works

We follow a systematic, transparent process to ensure every repair is reliable:

Gather details from operators about symptoms, error codes, or irregular results.

Run controlled tests to replicate and observe the issue in real time.

Fix faults using genuine spare parts and expert methods.

Provide clear explanations of findings and suggest corrective actions (repair, calibration, part replacement, or process adjustment).

Discuss options and costs before any further service is carried out.

Ensure the issue does not recur and provide preventative advice.

Our Repair Services vs Others

| Ours | Others |

|---|---|

Systematic checks – step-by-step diagnosis to find the real cause. | Guesswork – surface fixes without solving the root issue. |

Modern tools – use of meters, sensors, and software for accuracy. | Outdated methods – rely only on visual checks or trial and error. |

Clear reports – customers get troubleshooting results and next steps. | No updates – customers left unsure about the problem. |

Why Choose Us

Obsnap Automation has built a reputation as a reliable partner for industrial repair services in Malaysia. Here’s why businesses choose us:

Systematic Approach

Structured diagnostic processes to identify the true cause of failure.

Experienced Engineers

A team with combined expertise in mechanical, electrical, and automation systems.

Advanced Tools

Equipped with modern diagnostic instruments for precise fault-finding.

Comprehensive Reporting

Detailed findings, solutions, and preventive recommendations provided to every customer.

Local Support

Fast response and on-site troubleshooting services across Malaysia.

Commitment to Uptime

Focused on not just fixing, but ensuring long-term operational stability.

What Clients Think About Us

Our clients trust us to deliver reliable, high-quality labeling and automation solutions. Here’s what they had to say:

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

Troubleshooting identifies the root cause of the issue, while repair fixes the problem. In many cases, we provide both as part of a complete solution.

It depends on the complexity of the issue. Our team works quickly but thoroughly to identify the problem without compromising accuracy.

Yes. Our engineers are trained across multiple disciplines, including mechanical, electrical, and automation systems.

Absolutely. We always share preventive recommendations so you can avoid future downtime.