At Obsnap Automation, we specialise in providing comprehensive automation services,

That help industries improve efficiency, accuracy, and long-term reliability. With decades of hands-on engineering experience, we support manufacturers, laboratories, and production facilities in optimising their equipment performance through customised automation solutions.

Benefits of Factory Automation

In today’s competitive market, efficiency and consistency aren’t optional—they’re essential. Manual processes create delays, errors, and rising labor costs. Factory automation eliminates these barriers by streamlining production and boosting reliability. With Obsnap Automation’s tailored solutions, you can achieve:

Streamlined Operations

Our automation systems simplify complex processes, allowing your production to run faster and more efficiently with minimal human intervention.

Increased Productivity

Automated systems reduce manual work, eliminate bottlenecks, and help you achieve higher output with consistent quality.

Improved Accuracy & Consistency

Automation ensures precise control, reducing errors and variations in your production or processes.

Reduced Downtime

With integrated monitoring and preventive maintenance, your machines stay operational longer, minimizing costly interruptions.

Cost Efficiency

Optimized automation reduces labor costs, material waste, and energy consumption, improving your overall profitability.

Enhanced Safety

Automation minimizes human exposure to hazardous or repetitive tasks, improving workplace safety.

Scalable & Flexible Solutions

Our systems are designed to grow with your business, easily adapting to new processes, products, or production volumes.

Expert Support & Maintenance

We provide full installation, commissioning, and ongoing support, ensuring your automation systems perform reliably from day one.

Industries We Serve

Our automation solutions are designed to fit a diverse range of industries where precision, consistency, and efficiency are vital:

Electronics Manufacturing

Automotive & Transportation

Food & Beverage

Pharmaceuticals

Renewable Energy

Consumer Goods & Packaging

Automation Solutions We Provide

Our repair expertise spans a diverse range of equipment. Whether mechanical, hydraulic, or electronic, our engineers have the tools and training to bring them back to life:

PLC & Control Systems

Design, programming, and integration of control systems for reliable factory operations.

Robotic Integration

Robotic arms and automated handling systems for assembly, welding, and inspection tasks.

Machine Vision & Inspection

Advanced vision systems for precise quality assurance and defect detection.

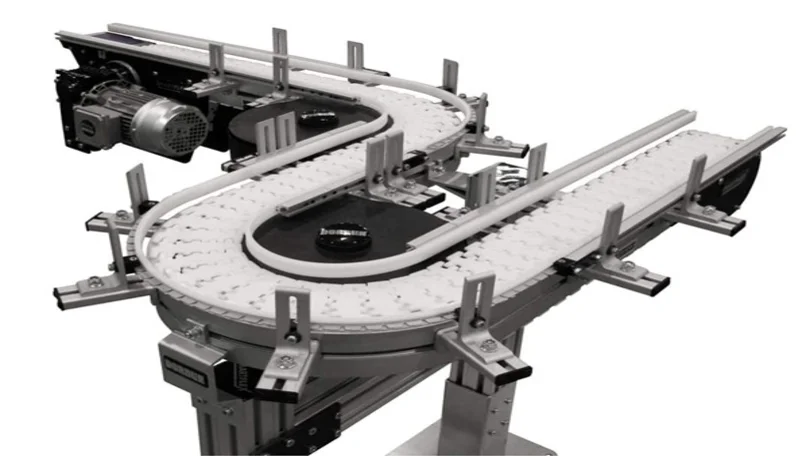

Conveyor & Material Handling Systems

Automated logistics to keep production lines moving smoothly.

Labeling & Marking Systems

Consistent, automated product identification for compliance and traceability.

Data Acquisition & Monitoring

Real-time tracking of equipment performance to enable predictive maintenance.

How It Works

Our approach ensures every automation project is aligned with your operational needs:

We analyze your production process and identify opportunities for automation.

Our engineers develop a customized solution tailored to your business requirements.

We deploy automation systems with minimal disruption to your operations.

Every system undergoes rigorous testing to ensure safety, reliability, and efficiency.

Your team receives hands-on training to operate and maintain the system confidently.

We provide continuous support and upgrades as your business scales.

Our Repair Services vs Others

| Our Factory Automation | Others |

|---|---|

Streamlined workflow – machines, sensors, and software work together seamlessly. | Manual processes – slower, repetitive, and prone to errors. |

Scalable systems – automation grows with your business needs. | Rigid setups – costly and difficult to upgrade. |

Live updates – operators get instant alerts when issues happen. | Blind spots – little to no visibility on production status. |

Why Choose Us

Obsnap Automation is trusted by Malaysian industries to deliver automation solutions that make a real difference:

Local Expertise

We understand the needs of Malaysian industries and provide responsive, on-site support.

Industry 4.0 Ready

Our systems are designed to integrate with IoT, AI, and smart manufacturing platforms.

Custom Engineering

Every automation solution is built to fit your production environment, not the other way around.

Proven Track Record

Years of successful projects delivered across multiple industries.

End-to-End Service

From consultation to ongoing support, we are your long-term partner in automation.

Commitment to Quality

Every repair is backed by strict quality checks and service warranties.

What Our Customers Say

Real businesses trust Obsnap Automation for their labelling and automation needs. Here’s what some of them shared:

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

It’s the use of machines, control systems, and software to automate manufacturing processes, reducing manual effort while improving accuracy, speed, and efficiency.

Yes. Our solutions are designed to integrate with both new and existing setups, minimizing disruption.

Automation is an investment. While the upfront cost varies, the long-term savings from reduced labor, downtime, and errors often outweigh the initial expense.

Absolutely. We provide training, preventive maintenance, troubleshooting, and upgrades to ensure long-term performance.