Top Surface Labelling Machine

A compact labelling machine that delivers quick, consistent, and professional label application for bottles, jars, or flat surfaces.

Precision Labelling for Every Container Size

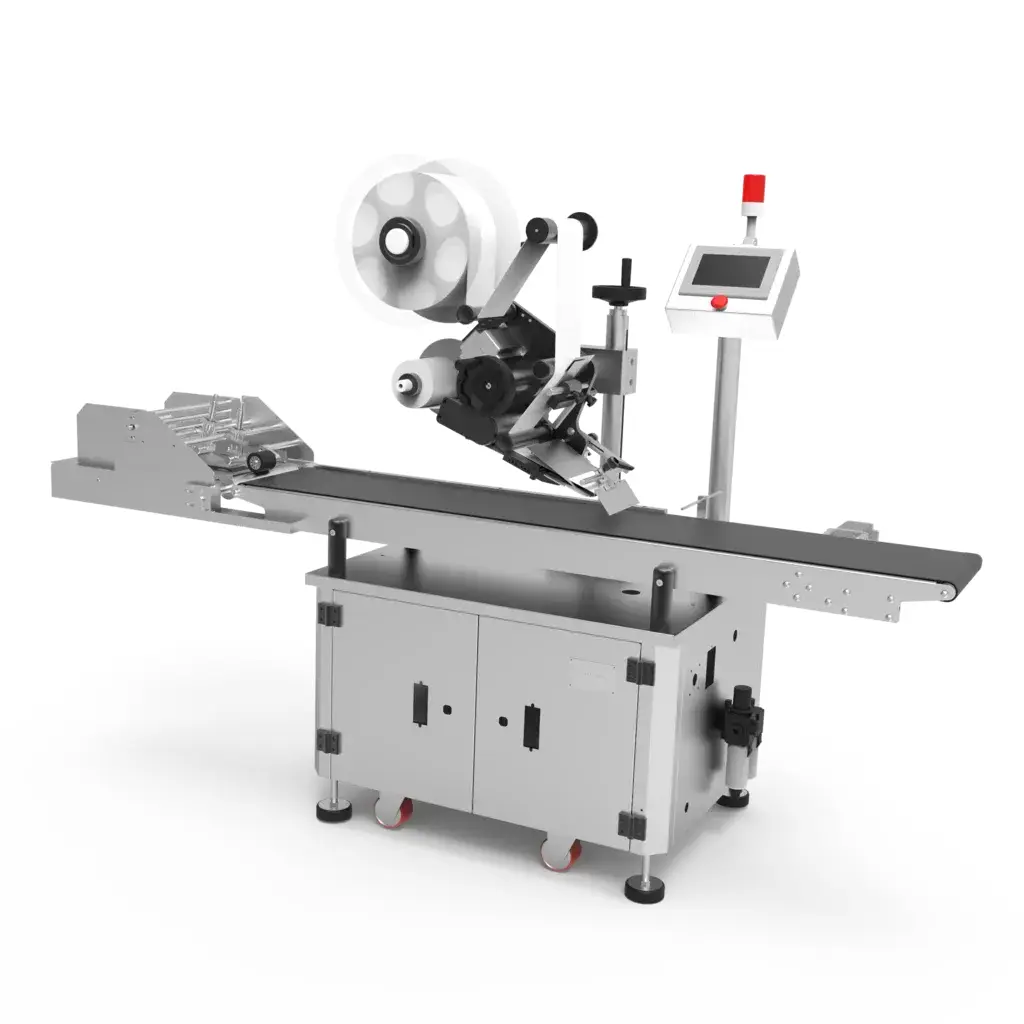

The WellPack Top Surface Labelling Machine is engineered for precise industrial labelling of flat and small round containers, making it an excellent choice for food, beverage, cosmetic, and pharmaceutical production lines. Its robust construction, featuring carbon steel, aluminium, and stainless steel, ensures reliable and durable operation even in high-demand environments.

Equipped with a servo-driven conveyor and an intuitive touch-screen interface, the WellPack Top Surface Labelling Machine allows easy adjustment for different container sizes and label formats. With consistent accuracy and adaptable speed settings, it supports diverse production needs while maintaining top-quality results on every product.

Key Features

Our WellPack Top Surface Labelling Machine is designed with advanced technology to streamline your labelling process:

High Precision Labelling

Maintains ±1 mm accuracy for consistent, professional-quality results.

Servo-Driven Conveyor

Ensures stable, smooth, and reliable label application.

Touch Screen Control

Easy-to-use interface for quick adjustments and monitoring.

Flexible Design

Capable of handling both flat and round surfaces, making it suitable for diverse packaging needs.

Fast Changeover

Quickly switch between different products, reducing downtime in production.

Durable Construction

Built from industrial-grade materials (carbon steel, aluminium, stainless steel) for long-term use.

Applications in Action

Our WellPack Top Surface Labelling Machine fits seamlessly into a variety of industries:

Food & Beverages

Labelling trays, lids, jars, cans, and bottles for sauces, snacks, drinks, and ready-to-eat packaging.

Pharmaceuticals

Accurate application of safety labels, dosage instructions, and compliance information on boxes, blister packs, and bottles.

Cosmetics & Personal Care

Perfect for flat containers such as cosmetic cases, cream jars, shampoo bottles, and skincare packaging.

Industrial & Chemical Products

Reliable labelling for oils, lubricants, and chemical containers requiring detailed front & back information.

Automation & Automotive

Supports labelling of components, spare parts, and packaging used in automated production lines.

Logistics & Warehouse

Useful for product identification, barcode labelling, and batch tracking on cartons and containers.

By handling a wide range of product shapes, sizes, and packaging materials, this machine adapts easily to different production requirements.

Compatible Label Materials

Our Top Surface Labelling Machine supports a variety of packaging materials, giving businesses full flexibility

Plastic containers

PET, HDPE, PP bottles, jars, trays, and lids.

Film packaging

Shrink wraps, sleeves, flexible pouches, and sachets.

Glass containers

Bottles and jars for food, beverages, cosmetics, and pharmaceuticals.

Metal packaging

Cans, tins, and other rigid containers.

Paper & Cardboard

Cartons, boxes, and trays.

Our Top Surface Labelling Machines

OBS - 113

Optimized for flat products

Engineered to apply labels accurately on trays, cartons, blister packs, and lids. Its ±1mm accuracy ensures every label is aligned correctly, even at higher speeds.

Compact build

With a space-saving frame, this 120kg unit is designed to fit into smaller production areas while still delivering industrial-grade reliability.

Consistent output

Operates at up to 100 pcs/min, making it well-suited for SMEs and short-to-medium batch runs without compromising quality.

Durable construction

Built with carbon steel, aluminium, and stainless steel for long-lasting performance and easy maintenance.

Ease of use

Quick setup and operator-friendly controls minimize downtime during product changeovers.

Optimized for flat products

Engineered to apply labels accurately on trays, cartons, blister packs, and lids. Its ±1mm accuracy ensures every label is aligned correctly, even at higher speeds.

Compact build

With a space-saving frame, this 120kg unit is designed to fit into smaller production areas while still delivering industrial-grade reliability.

Consistent output

Operates at up to 100 pcs/min, making it well-suited for SMEs and short-to-medium batch runs without compromising quality.

Durable construction

Built with carbon steel, aluminium, and stainless steel for long-lasting performance and easy maintenance.

Ease of use

Quick setup and operator-friendly controls minimize downtime during product changeovers.

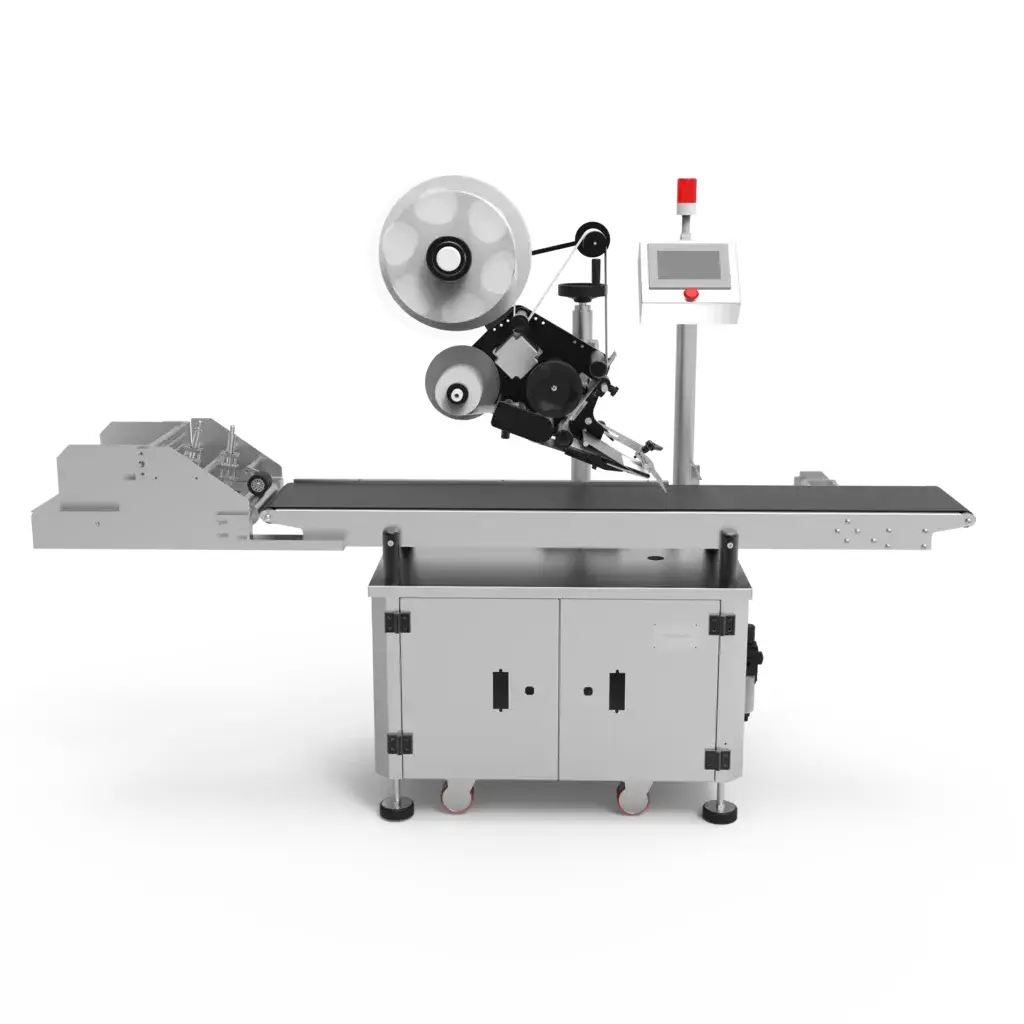

OBS - 115

Dual-purpose labelling

Unlike the OBS-113, this model handles both flat surfaces and round bottles, giving you greater versatility in one unit.

High throughput

Capable of 50–200 pcs/min, it’s tailored for medium-to-large production lines where speed and efficiency are critical.

Supports multiple label materials

Works seamlessly with both plastic and film labels, making it suitable for industries that require premium or flexible labelling options.

Robust and scalable

Heavier-duty build at 180kg with extended dimensions, ensuring stability even in high-speed operations.

Ideal for growing businesses

A solid investment if you plan to scale up production or diversify packaging formats, from beverage bottles to multipurpose cartons.

Dual-purpose labelling

Unlike the OBS-113, this model handles both flat surfaces and round bottles, giving you greater versatility in one unit.

High throughput

Capable of 50–200 pcs/min, it’s tailored for medium-to-large production lines where speed and efficiency are critical.

Supports multiple label materials

Works seamlessly with both plastic and film labels, making it suitable for industries that require premium or flexible labelling options.

Robust and scalable

Heavier-duty build at 180kg with extended dimensions, ensuring stability even in high-speed operations.

Ideal for growing businesses

A solid investment if you plan to scale up production or diversify packaging formats, from beverage bottles to multipurpose cartons.

Labelling Machine Specificiations

| Model | OBS - 113 | OBS - 115 |

|---|---|---|

| Voltage | AC 220V, 50Hz | AC 220V, 50Hz |

| Dimension | 1600(L)*900(W)*1450(H) (mm) | 2200(L)*700(W)*1400(H) (mm) |

| Speed | 0-100 pcs/min | 50-200 pcs/min |

| Label Material | Plastic | Plastic and Film |

| Material | Carbon steel, aluminium and stainless steel | Carbon steel, aluminium and stainless steel |

| Function | Stick labels for flat surfaces | Stick labels for round and flat bottles |

| Labelling Accuracy | ± 1mm | ± 1mm |

| Weight | 120kg | 180kg |

| Usage | Flat product labelling | Adhesive bottle labelling |

Which WellPack Top Surface Labelling Machine is Right for You?

Selecting the right top surface labelling model depends on your container sizes, label formats, and production requirements.

To help you decide, here’s a clear comparison of our four FlexiLine top surface labelling machines:

| Feature | OBS - 113 | OBS - 115 |

|---|---|---|

| Best For | Flat products such as trays, cartons, pouches, lids, and blister packs. | Both flat surfaces and round bottles like beverages, shampoo, skincare, and supplements. |

| Production Scale | Small to medium operations where efficiency and affordability matter most. | Medium to large production with higher speed and flexibility for diverse packaging. |

| Why Choose It |

|

|

| Labelling Speed | 0–100 pcs/min (operator-adjustable) | 50–200 pcs/min, suitable for higher output |

| Material Build | Carbon steel, aluminium, and stainless steel for durability. | Carbon steel, aluminium, and stainless steel for heavy-duty performance. |

| Machine Weight | 120 kg – lightweight, easy to relocate if needed. | 180 kg – more stable for continuous production runs. |

| Dimensions | 1600(L) × 900(W) × 1450(H) mm – fits tighter spaces. | 2200(L) × 700(W) × 1400(H) mm – longer design for faster workflow. |

| Ideal Applications | Bakeries, cosmetic cases, blister packs, small food packaging, pharmaceuticals. | Beverage lines, skincare bottles, supplement jars, multipurpose packaging industries. |

Why Businesses Choose the WellPack Top Surface Labelling Machine

Choosing the right labelling machine is not just about speed, it’s about consistency, flexibility, and long-term reliability.

Here’s why companies trust the WellPack Top Surface Labeller:

Built to Last

Protect Your Brand Image

After-Sales Support

Time & Cost Savings

Scalable Solution

Multi-Industry Use

Watch WellPack Top Surface Labelling Machine in Action

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

Perfect for flat items like cartons, trays, blister packs, jar lids, books, electronic boxes, and cosmetic cases.

Yes, depending on the model, it can achieve 50–200 pcs/min with consistent accuracy.

Works with paper, plastic, film, and other adhesive label types for various industries.

Food & beverage, pharmaceuticals, cosmetics, electronics, logistics, and education sectors.

Absolutely. Its user-friendly controls and compact design make it easy for operators to set up and maintain.