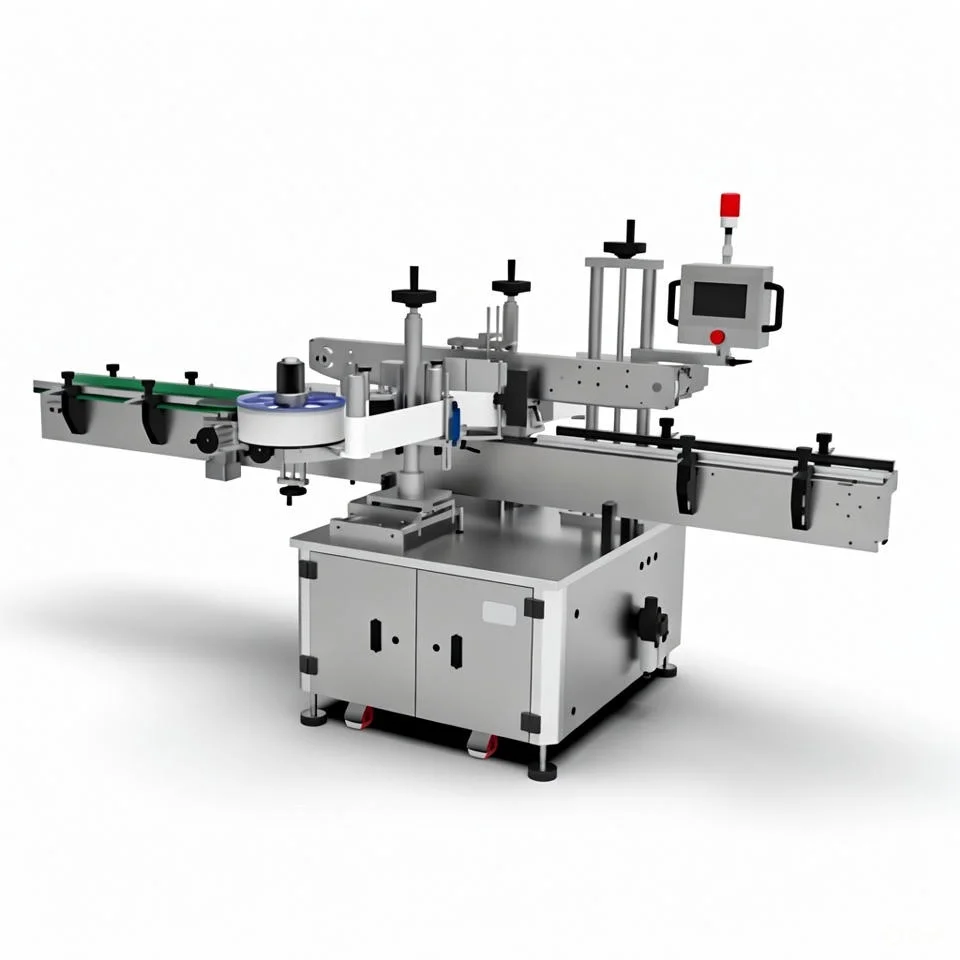

Front & Back Side Labelling Machine

A compact labelling machine that delivers quick, consistent, and professional label application for bottles, jars, or flat surfaces.

Precision Labelling for Every Container Size

The WellPack Front & Back Side Labelling Machine applies labels on both the front and back of flat or oval containers in a single pass, making it ideal for industries such as food & beverages, cosmetics, pharmaceuticals, household goods, and specialty packaging.

Designed for precision and assembled with high-quality components from trusted global manufacturers, the WellPack Front & Back Side Labelling Machine delivers fast, accurate, and durable performance, ensuring consistent, professional results on your production line.

Key Features

Our labelling machine is more than just efficient, it’s built to transform your production line

High Precision (±1mm)

Ensures your labels are applied cleanly and consistently, maintaining brand reputation.

Servo & Step Motor Technology

Guarantees smooth, stable, and reliable operation.

User-Friendly Touchscreen Control

Intuitive interface for setup, adjustments, and real-time monitoring.

Flexible Label Size Handling

Accepts labels between 25–200 mm (length) and 20–170 mm (width).

Dual-Sided Application in One Pass

Label the front and back simultaneously, reducing cycle times and boosting efficiency.

Durable Construction

Built with components from globally reputable manufacturers for long-lasting reliability.

Applications in Action

Our WellPack Front & Back Side Labelling Machine isn’t just any labelling machine, it’s a solution tailored for diverse industries

Food & Beverages

Apply front/back nutritional info and branding labels on bottles, jars, or cartons.

Pharmaceuticals

Guarantee accurate placement for compliance labels, barcodes, and safety instructions.

Cosmetics & Personal Care

Ensure perfect product presentation on lotions, shampoos, and creams where design consistency is key.

Household Products

Reliable labelling for detergents, cleaners, and daily-use packaged goods.

Specialty Packaging

Flexible enough for unique product shapes and limited-edition packaging.

Education

From lab equipment to stationery and supplies, our machines provide clean, durable labels that are easy to identify and professional-looking.

This means you don’t need multiple machines for different packaging as one system can cover it all.

Compatible Label Materials

Engineered for versatility, this Front & Back Side Labelling Machine can handle

Plastic Containers

PET, HDPE, and PP bottles & jars commonly used in food, beverages, and cosmetics.

Glass bottles & jars

From sauces to premium cosmetic packaging.

Metal cans & tins

Suitable for food products, paints, and household goods.

Cardboard boxes & cartons

Perfect for pharmaceuticals and specialty goods.

Flexible packaging

Pouches, sachets, and shrink-wrapped packs, ensuring your labels adhere securely.

Our Front & Back Side Labelling Machine

OBS - 712

Dual labelling heads

Applies both front and back labels in one pass, improving efficiency and ensuring consistent alignment.

High-speed performance

Handles up to 200 pcs/min thanks to its servo-driven system, ideal for large production lines.

Wide product compatibility

Supports containers of various shapes and sizes, making it versatile for multiple industries.

Precision accuracy

Maintains ±1mm labelling accuracy with smart sensors for reliable and professional results.

Robust structure

Stainless steel build ensures durability and stability during continuous high-speed operation.

Easy operation

User-friendly controls allow quick adjustments and fast product changeovers.

Dual labelling heads

Applies both front and back labels in one pass, improving efficiency and ensuring consistent alignment.

High-speed performance

Handles up to 200 pcs/min thanks to its servo-driven system, ideal for large production lines.

Wide product compatibility

Supports containers of various shapes and sizes, making it versatile for multiple industries.

Precision accuracy

Maintains ±1mm labelling accuracy with smart sensors for reliable and professional results.

Robust structure

Stainless steel build ensures durability and stability during continuous high-speed operation.

Easy operation

User-friendly controls allow quick adjustments and fast product changeovers.

Labelling Machine Specificiations

| Model | OBS-712 |

|---|---|

| Voltage | AC 220V, 50Hz, Single phase |

| Machine Dimension | 3000(L)*1550(W)*1450(H)(mm) |

| Conveyor Height | 700 mm |

| Labelling Accuracy | ± 1 mm |

| Labelling Speed | 10-200 pcs/min |

| Product Size | 20-500(L)*20-110(W)*30-350(H)(mm) |

| Label Size (Backing Paper) | 25-200(L)*20-170(W)(mm) |

| Max. Label Roll Diameter | 300 mm (outer), 76 mm (inner) |

| Power | 2kW |

| Surrounding Temperature | 20-45°C |

| Surrounding Humidity | 15-85% |

| Air Supply | Not Required |

| Machine Weight | 250kg |

Why Businesses Choose Our Desktop Labelling Machines

When investing in a labelling solution, you need more than just a machine; you need reliability, consistency, and long-term value.

Here’s why WellPack machines stand out:

Maximize Efficiency

Protect Your Brand Image

Proven Reliability

Cost-Effective Solution

Scalability

Industry Versatility

Watch WellPack Front & Back Side Labelling Machine in Action

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

It’s designed for flat, oval, or rectangular bottles and containers where two labels (front & back) are required. Suitable for cosmetics, beverages, cleaning products, and personal care packaging.

The machine accommodates a wide range: 20–500mm in length, 20–110mm in width, and 30–350mm in height.

It delivers high precision with ±1mm accuracy, even at high speeds of 10–200 pcs/min.

Yes. Unlike some other systems, this model does not require an air supply, reducing operating costs and maintenance.

Yes, we offer full installation, operator training, and local after-sales service in Malaysia.