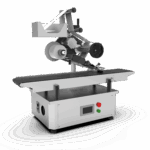

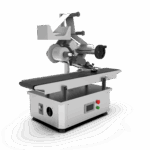

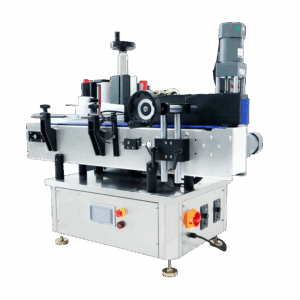

Desktop Labelling Machine

A compact labelling machine that delivers quick, consistent, and professional label application for bottles, jars, or flat surfaces.

Precision Labelling for Every Container Size

The WellPack Desktop Labelling Machine is designed to deliver high-accuracy labelling for small containers such as bottles, jars, and specialty packaging. Its compact size allows for easy installation in production environments with limited space, while the step motors and servo-driven conveyor ensure stable and precise label placement.

Operating the WellPack Desktop Labelling Machine is simple thanks to its intuitive touch screen interface, and the machine can be quickly adapted to accommodate a variety of container sizes and label formats. The desktop labelling machine is available in several models (OBS-113ET, OBS-113T, OBS-211T, and OBS-212T), offering consistent, high-quality performance and exceptional versatility across different production settings.

Key Features

Our WellPack Desktop Labelling Machine is designed with advanced technology to streamline your labelling process:

High Precision

Consistently achieves ±1mm labelling accuracy, minimizing waste and rework.

Servo-Driven Conveyor & Step Motor

Guarantees stable, smooth, and reliable performance.

Touch Screen Control

Simple, intuitive interface for easy setup and real-time monitoring.

Flexible Design

Supports a wide variety of label sizes and container shapes.

Quick Changeover

Fast switching between different products and labels with minimal downtime.

Durable Construction

Engineered with robust components for long-lasting performance.

Applications in Action

Our WellPack Desktop Labelling Machine fits seamlessly into a variety of industries:

Food & Beverages

Label jars, bottles, and sachets with precision branding and compliance details.

Pharmaceuticals

Apply safety-compliant labels on vials, syringes, and bottles with complete accuracy.

Cosmetics & Personal Care

Achieve flawless, premium packaging for luxury skincare, fragrance, and beauty products.

Electronics & Components

Label small parts and packages efficiently, maintaining traceability and quality control.

Automation & Automotive

Labels on automotive components and automated production equipment require precision and reliability

Education

From lab equipment to stationery and supplies, our machines provide clean, durable labels that are easy to identify and professional-looking.

Each application benefits from consistent labeling, reduced waste, and faster production, letting your business scale efficiently.

Compatible Label Materials

Our Desktop Labelling Machine works with a broad range of label materials:

Paper & Polyester

Standard labels and high-quality prints.

Polyethylene & Vinyl

Flexible, durable, and suitable for curved or irregular containers.

Specialty Synthetics (e.g., Polypropylene, Polyimide)

These materials are resistant to moisture, chemicals, extreme temperatures, and heavy wear.

Our Desktop Labelling Machines

OBS - 113ET

Compact and efficient

With its 0.8kW motor and single-phase power supply, this machine provides stable performance without heavy power consumption, making it perfect for small to medium production runs.

Fast but precise

Speeds of 20–120 pcs/min combined with ±1mm accuracy ensure labels are applied neatly even at higher throughput, which is ideal for products like cosmetics, food jars, or daily goods.

User-friendly size

At only 1150(L) × 600(W) × 1050(H) mm and weighing 100kg, it fits comfortably on a workbench or small production area without requiring large factory space.

Versatile product handling

Can accommodate items from 30–400mm long and 10–200mm wide, making it suitable for a wide variety of packaging shapes and label styles.

Compact and efficient

With its 0.8kW motor and single-phase power supply, this machine provides stable performance without heavy power consumption, making it perfect for small to medium production runs.

Fast but precise

Speeds of 20–120 pcs/min combined with ±1mm accuracy ensure labels are applied neatly even at higher throughput, which is ideal for products like cosmetics, food jars, or daily goods.

User-friendly size

At only 1150(L) × 600(W) × 1050(H) mm and weighing 100kg, it fits comfortably on a workbench or small production area without requiring large factory space.

Versatile product handling

Can accommodate items from 30–400mm long and 10–200mm wide, making it suitable for a wide variety of packaging shapes and label styles.

OBS - 113T

Similar performance with improved ergonomics

Like the OBS-113ET, it runs at 20–120 pcs/min with the same ±mm precision, but its slightly taller build (1156mm height) improves operator accessibility during long shifts.

Reliable operation

Shares the same 0.8kW power rating, which keeps energy consumption low while maintaining stable speed and accuracy.

Flexible labelling range

Supports the same 10–150mm label size range, which is perfect for industries where products come in different SKUs with varied packaging.

Similar performance with improved ergonomics

Like the OBS-113ET, it runs at 20–120 pcs/min with the same ±mm precision, but its slightly taller build (1156mm height) improves operator accessibility during long shifts.

Reliable operation

Shares the same 0.8kW power rating, which keeps energy consumption low while maintaining stable speed and accuracy.

Flexible labelling range

Supports the same 10–150mm label size range, which is perfect for industries where products come in different SKUs with varied packaging.

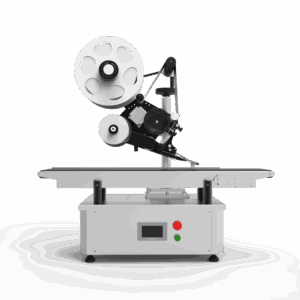

OBS - 211T

Higher power for heavy-duty use

Powered by 1.5kW, this model can handle more demanding labelling applications, especially where larger rolls and longer operating hours are required.

Speed advantage

Capable of up to 150 pcs/min, making it the fastest in the desktop range, suitable for businesses scaling up production without moving to full industrial lines.

Designed for cylindrical products

Supports diameters from 10–100mm and heights up to 300mm, making it a strong choice for bottles, tubes, and vials.

Compact but sturdy

Despite higher power, it keeps the same 100kg weight, balancing stability with portability across production floors.

Higher power for heavy-duty use

Powered by 1.5kW, this model can handle more demanding labelling applications, especially where larger rolls and longer operating hours are required.

Speed advantage

Capable of up to 150 pcs/min, making it the fastest in the desktop range, suitable for businesses scaling up production without moving to full industrial lines.

Designed for cylindrical products

Supports diameters from 10–100mm and heights up to 300mm, making it a strong choice for bottles, tubes, and vials.

Compact but sturdy

Despite higher power, it keeps the same 100kg weight, balancing stability with portability across production floors.

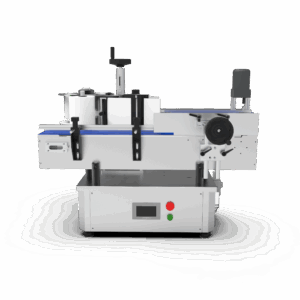

OBS - 212T

Built for precision on larger products

Unlike the OBS-211T, this unit is optimized for larger bottles and jars (20–100mm diameter, up to 250mm height), where labels need to wrap neatly without distortion.

Steady and accurate

Operates at 10–40 pcs/min, which is slower, but this deliberate pacing ensures high accuracy (±1mm) on bulkier products where misalignment would be noticeable.

Handles bigger labels

Supports label sizes up to 300mm length × 150mm width, allowing brands to include more detailed branding or regulatory information.

Air-assisted system

Requires 0.5–0.8 MPa air supply, which helps stabilize label application on larger containers, ensuring smooth adhesion and reducing bubbles or creases.

Built for precision on larger products

Unlike the OBS-211T, this unit is optimized for larger bottles and jars (20–100mm diameter, up to 250mm height), where labels need to wrap neatly without distortion.

Steady and accurate

Operates at 10–40 pcs/min, which is slower, but this deliberate pacing ensures high accuracy (±1mm) on bulkier products where misalignment would be noticeable.

Handles bigger labels

Supports label sizes up to 300mm length × 150mm width, allowing brands to include more detailed branding or regulatory information.

Air-assisted system

Requires 0.5–0.8 MPa air supply, which helps stabilize label application on larger containers, ensuring smooth adhesion and reducing bubbles or creases.

Labelling Machine Specificiations

| Model | OBS - 113ET | OBS - 113T | OBS - 211T | OBS - 212T |

|---|---|---|---|---|

| Power | 0.8kW | 0.8kW | 1.5kW | 1kW |

| Power Supply | AC 220V, 50Hz, Single Phase | AC 220V, 50Hz, Single Phase | AC 220V, 50Hz, Single Phase | AC 220V, 50Hz, Single Phase |

| Labelling Accuracy | ± 1 mm | ± 1 mm | ± 1 mm | ± 1 mm |

| Labelling Speed | 20-120 pcs/min | 20-120 pcs/min | 10-150 pcs/min | 10-40 pcs/min |

| Machine Dimension | 1150(L)*600(W)*1050(H)(mm) | 1156(L)*600(W)*1150(H)(mm) | 1100(L)*1050(W)*850(H)(mm) | 1100(L)*1070(W)*850(H)(mm) |

| Conveyor Height | 450 ± 50mm | 450 ± 50mm | 500 ± 50mm | 500 ± 50mm |

| Machine Net Weight | 100kg | 100kg | 100kg | 100kg |

| Label Size (Backing Paper) | 10-150(L)* 10-150(W)(mm) | 10-150(L)* 10-150(W)(mm) | 15-310(L)* 10-100(W)(mm) | 20-300(L)* 10-150(W)(mm) |

| Product Size | 30-400(L)* 10-200(W)(mm) | 30-400(L)* 10-200(W)(mm) | 10-100(Diameter)*10-300 (Height)(mm) | 20-100(Diameter)*10-250(Height)(mm) |

| Surrounding Humidity | 15-85% | 15-85% | 15-85% | 15-85% |

| Working Environment | 10-40°C | 10-40°C | 20-45°C | 20-45°C |

| Air Supply | Not required | Not required | Not required | 0.5-0.8 MPa, 10L/min |

Which WellPack Desktop Labelling Machine is Right for You?

Selecting the right desktop model depends on your container sizes, label formats, and production requirements.

To help you decide, here’s a clear comparison of our four FlexiLine desktop labelling machines:

| Model | Best For | How It Works | Advantages |

|---|---|---|---|

OBS-113ET / 113T | Small to medium containers | Manual or semi-automatic labelling on jars, bottles, or small packaging | • Cost-effective • Space-saving • Easy to operate • Ideal for startups & SMEs |

OBS-211T | Slightly larger containers | Flexible labelling for a variety of label sizes and shapes | • Supports more versatile label dimensions • Higher speed • Reliable accuracy |

OBS-212T | Specialized or high-volume labelling | Handles taller or wider containers in compact areas | • Designed for high-volume or specialized production • Ensures precise, consistent placement |

| All Models | Multiple industries | Desktop form factor with servo-driven conveyor | • Compact footprint • Durable construction • Quick changeovers • Reduces waste |

Why Businesses Choose Our Desktop Labelling Machines

When investing in a labelling solution, you need more than just a machine; you need reliability, consistency, and long-term value.

Here’s why WellPack machines stand out:

Maximize Efficiency

Protect Your Brand Image

Future-Proof Your Production

Save on Training & Labour Costs

Scale with Confidence

Space-Saving Advantage

Watch WellPack Desktop Labelling Machine in Action

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

WellPack Desktop Labelling Machine is designed for small to medium containers such as bottles, jars, sachets, and specialty packaging. Depending on the model, it can accommodate containers from 30mm up to 400mm in length and 10mm to 200mm in width/diameter, making it versatile for startups, SMEs, and niche production lines.

Yes! Works with paper, polyester, polyethylene, vinyl, and specialty synthetics for demanding conditions.

Speeds range from 10–150 pcs/min, depending on the model, while maintaining ±1mm accuracy.

Yes, the touchscreen interface allows quick setup, changeovers, and monitoring, reducing training time and errors.

Absolutely. We offer installation, training, servicing, and local technical support in Malaysia.