Smart Glue Dispensing Machine with 2 Adjustable Flow Control

A compact and intelligent system that provides highly precise glue control, delivering cleaner and more professional finishes. By optimizing adhesive usage, it helps reduce material costs while supporting faster operations, resulting in smoother, more reliable, and consistent packaging performance.

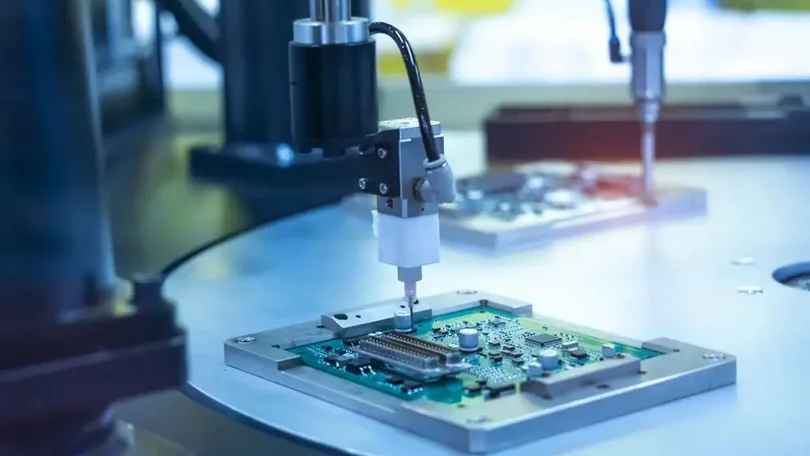

Precision automation for flawless adhesive performance

The WellPack Smart Glue Dispensing Machine with 2 Adjustable Flow Control is designed to deliver highly precise and automated adhesive dispensing with enhanced flexibility. The dual flow control system allows operators to adjust glue flow with precision for two different dispensing points on the workspace, making it ideal for electronics assembly, industrial manufacturing, automotive parts, and cosmetics packaging.

Equipped with a user-friendly LCD interface or handheld controller, 3-axis motion system, and optional micro-adjustment stage, this machine ensures repeatable accuracy, faster setup, and streamlined program management via USB. Its robust construction supports both standalone operation and integration into existing production lines.

Key Features

Our WellPack Smart Glue Dispensing Machine is designed with advanced technology to streamline your labelling process:

Precise Positioning

X-Y micro-adjustment stage ensures accurate alignment of components and fixtures.

Optional Vision Positioning

Improves accuracy for complex or 3D surfaces.

Controlled Dispensing Speed

High-precision stepper motors regulate dispensing speed, reducing errors like stringing or glue accumulation.

Standalone Operation & Easy Installation

Operates independently without the need for an external computer; simple setup and operation.

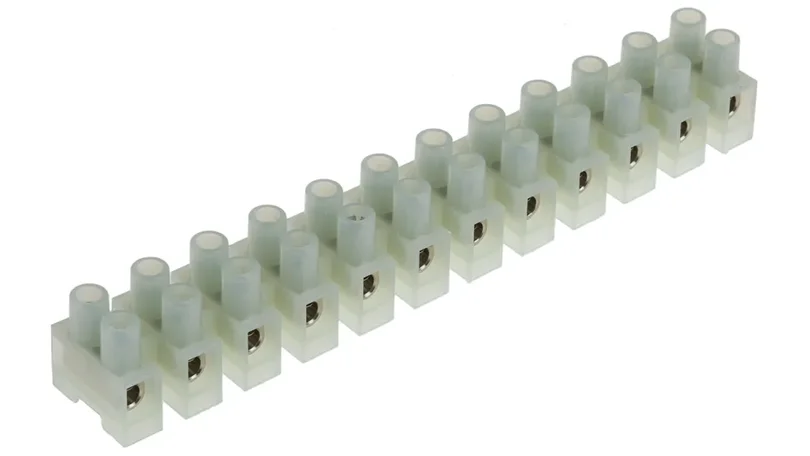

Dual Adjustable Flow Control

Precisely control two separate dispensing points on the workspace for complex layouts.

High-Strength Machine Body

One-piece casting structure with integrated CNC workbench ensures X/Y/Z perpendicularity and machine stability.

User-Friendly Programming

Icon-based teaching pendant allows quick programming of dispensing paths, matrix copying, offset adjustments, and calibration point settings.

Enhanced User Experience

Magnetic/photoelectric switches with dispensing count alarms allow real-time monitoring of the dispensing process.

Applications in Action

The WellPack Smart Glue Dispensing Machine is versatile across multiple industries, offering precision, repeatability, and speed

Electronics & Electrical Components

Apply adhesives to printed circuit boards (PCBs), connectors, sensors, and electronic assemblies with high accuracy.

Packaging & Consumer Goods

Automate glue application for bottles, jars, boxes, cartons, and inserts in food, beverage, and cosmetic packaging.

Medical Devices & Precision Equipment

Precision dispensing for syringes, vials, sensors, and delicate instruments.

Industrial Automation & Prototyping

Ideal for small-batch production, product development, or prototyping where precise adhesive application is critical.

Packaging

Used in food, beverage, and consumer goods production lines for carton sealing, tray forming, and product labeling.

Education

Perfect for training institutions and technical colleges to demonstrate real-world automation principles in mechatronics, robotics, and manufacturing courses.

Each application benefits from consistent dispensing, reduced waste, and faster production, letting your business scale efficiently.

Smart Glue Dispensing Machine Specifications

| Model | JT-D4400 | JT-D4410 |

|---|---|---|

| Working Range (mm) | ||

| – X-axis | 400 mm | 400 mm |

| – Y1/Y2/Y3/Y4-axis | 400 mm | 400 mm |

| – Z-axis | 100 mm | 120 mm |

| Adhesive & Glue | Heating Temp. Range: 0–360°C | Heating Temp. Range: 0–360°C |

| Max Load (kg) | ||

| – Y-axis | 10 kg | 10 kg |

| – Z-axis | 5 kg | 5 kg |

| Moving Speed (mm/sec) | XY/Z-axis: 0.1–800 mm/s | XY/Z-axis: 0.1–800 mm/s |

| Resolution (mm/axis) | 0.01 mm/axis | 0.01 mm/axis |

| Repetitive Position Accuracy | ±0.01 mm/axis | ±0.01 mm/axis |

| Programme Display | Hand-held box or LCD (optional) | Hand-held box or LCD (optional) |

| Motor System | Servo Micro-step Motor | Servo Micro-step Motor |

| Interpolation Function | 3-axis (3D stereoscopic space for any route) | 3-axis (3D stereoscopic space for any route) |

| Driving Method | Conveyor & Synchronous driving belt | Conveyor & Synchronous driving belt |

| Direction & Axis | Three Axis: XYZ | Three Axis: XYZ |

| Programme Way | Hand knob or computer (optional) | Hand knob or computer (optional) |

| I/O Signal Port | 8 Inputs / 8 Outputs | 8 Inputs / 8 Outputs |

| External Interface | USB | USB |

| Power | AC220V 50/60Hz (optional) | AC220V 50/60Hz (optional) |

| Best Working Condition | Temp: 10–40°C, Humidity: 20–90% (no condensation) | Temp: 10–40°C, Humidity: 20–90% (no condensation) |

| Dimension (mm) | 635 × 575 × 600 mm | 635 × 575 × 600 mm |

| Weight (kg) | 60 kg | 100 kg |

Which WellPack Smart Glue Dispensing Machine is Right for You?

Selecting the right dispensing model depends on your container sizes, label formats, and production requirements.

To help you decide, here’s a clear comparison of our Smart Glue Dispensing Machine with 2 adjustable flow control machines:

| Model | Best For | How It Works | Applications & Ideal Industries | Advantages |

|---|---|---|---|---|

| JT-D4400 | • Small to medium products • Low–medium volume production | • Dual flow control for precise glue adjustment at two points • Hand-held or LCD programming • X-Y micro-adjustment stage | • Electronics: PCB components, small housings • Cosmetics: Jars, bottles • Automotive: Sensors, small parts • Industrial assembly: Small machinery components | • Compact design • High precision ±0.01mm • User-friendly teaching pendant • Flexible, adjustable flow control |

| JT-D4410 | • Medium–large products • High-volume or multi-point dispensing | • Dual flow control with larger Z-axis range • Icon-based teaching pendant • Supports complex 3D paths | • Automotive: Assemblies, brackets • Industrial: Mechanical parts requiring multiple adhesive points • Electronics: Medium PCBs or enclosures • Cosmetics & Pharma: Multi-unit containers | • Higher precision with larger capacity • Easy program transfer • Real-time monitoring with optional sensors • Versatile for multi-point dispensing |

Why Businesses Choose Our Smart Glue Dispensing Machine

When investing in a dispensing solution, you need more than just a machine; you need reliability, consistency, and long-term value.

Here’s why WellPack machines stand out:

Maximize Productivity

Ensure Accuracy

Flexible Application

Easy Setup & Programming

Reliable Construction

Standalone or Integrated

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

Small to medium components and assemblies require one or two controlled glue points.

Yes, the JT-D4410 model supports complex 3D dispensing paths.

XY/Z axis speed ranges from 0.1-800mm/sec depending on model.

Icon-based teaching pendant or USB upload makes programming quick and intuitive.

Optional vision positioning is available for complex or 3D components.