Advanced Automatic Glue Dispensing Machine

A compact, intelligent system that delivers precise glue control for cleaner finishes, lower material costs, and faster, more reliable packaging performance.

Precision automation for flawless adhesive performance

The WellPack Advanced Automatic Glue Dispensing Machine, proudly offered by Obsnap Automation, revolutionizes adhesive application by replacing manual dispensing with precision-controlled automation. Perfect for small to medium production environments, it ensures consistent glue application across flat, contoured, and slightly complex surfaces. Its compact design, intuitive LCD interface, and USB-programmable system enable fast setup, repeatable processes, and minimal downtime.

Available in multiple models (JT-D3210, JT-D3310, JT-D3410, JT-D3510), this WellPack machine provides the right solution for diverse production lines—from electronics assembly to packaging and automotive components—ensuring accuracy, speed, and reliability in every operation.

Key Features

Our WellPack Advanced Automatic Glue Dispensing Machine is designed with advanced technology to streamline your labelling process:

Automated Precision Dispensing

Eliminates inconsistencies caused by manual glue application, reducing waste, material cost, and product defects.

Optional Vision System

Enhances accuracy for precision components, critical in electronics, automotive, and medical industries.

Intuitive LCD Interface

Provides real-time monitoring, easy parameter adjustments, and user-friendly controls.

USB Program Management

Upload or download dispensing programs for repeatable precision and efficient process management.

3D Arc Interpolation

Supports true PTP and CP three-axis paths, making it ideal for 3D dispensing on complex or non-flat surfaces.

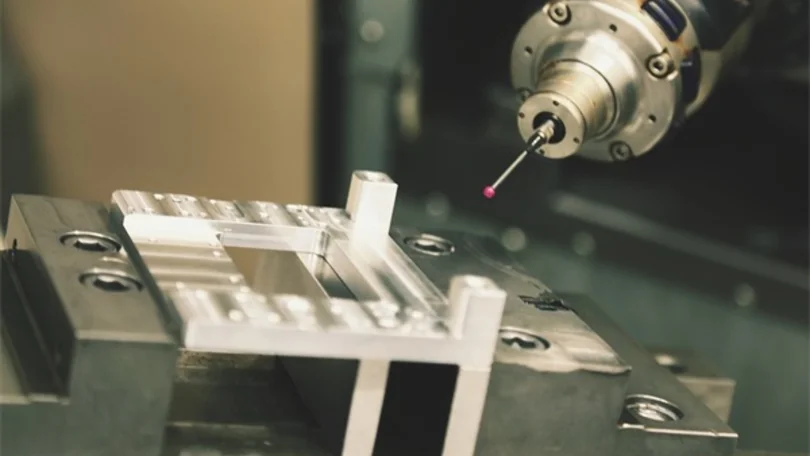

High-Strength Industrial Body

Constructed with a one-piece casting structure and integrated CNC workbench for superior stability and perpendicularity across X/Y/Z axes.

Applications in Action

The WellPack Advanced Automatic Glue Dispensing Machine is versatile across multiple industries, offering precision, repeatability, and speed

Electronics & Electrical Components

Apply adhesives to printed circuit boards (PCBs), connectors, sensors, and electronic assemblies with micron-level accuracy.

Automotive & Industrial Components

Dispense adhesives on gaskets, seals, sensors, connectors, and assembly parts with repeatable precision.

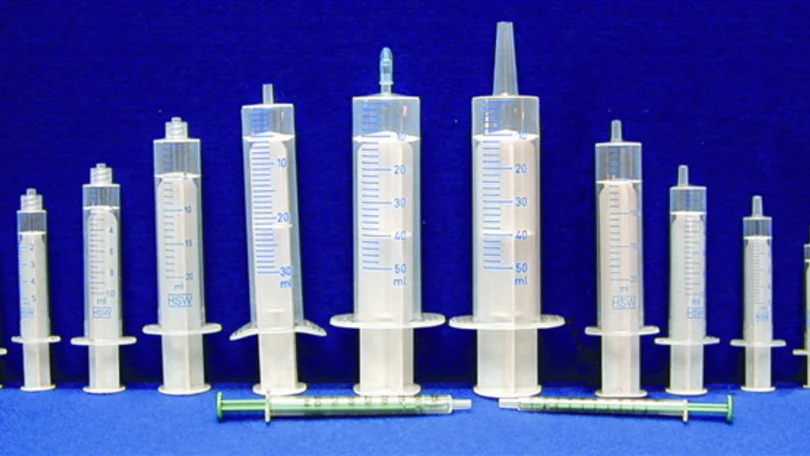

Medical Devices & Precision Equipment

Precision dispensing for syringes, vials, sensors, and delicate instrument assemblies.

Industrial Automation & Prototyping

Ideal for small-batch production, product development, or prototyping where precise adhesive application is critical.

Packaging

Used in food, beverage, and consumer goods production lines for carton sealing, tray forming, and product labelling.

Education

Perfect for training institutions and technical colleges to demonstrate real-world automation principles in mechatronics, robotics, and manufacturing courses.

Each application benefits from consistent dispensing, reduced waste, and faster production, letting your business scale efficiently.

Labelling Machine Specificiations

| Model | JT-D3210 | JT-D3310 | JT-D3510 | JT-D3510 |

|---|---|---|---|---|

| Working Range(mm) | ||||

| X-axis | 200mm | 300mm | 400mm | 500mm |

| Y-axis | 200mm | 300mm | 400mm | 500mm |

| Z-axis | 80mm | 80mm | 120mm | 100mm |

| Adhesive & Glue | ||||

| Temperature Range | 0-350°C | 0-350°C | 0-350°C | 0-350°C |

| Max. Load(kg) | ||||

| Y-axis | 10kg | 10kg | 10kg | 10kg |

| Z-axis | 5kg | 5kg | 5kg | 5kg |

| Moving Speed(mm/sec) | 0.1-800mm/sec | 0.1-800mm/sec | 0.1-800mm/sec | 0.1-800mm/sec |

| Resolution(mm/Axis) | 0.01mm/axis | 0.01mm/axis | 0.01mm/axis | 0.01mm/axis |

| Repetitive Positioning Accuracy | ±0.01mm/axis | ±0.01mm/axis | ±0.01mm/axis | ±0.01mm/axis |

| Programming Display | LCD Box | LCD Box | LCD Box | LCD Box |

| Motor System | Servo Micro-step Motor | Servo Micro-step Motor | Servo Micro-step Motor | Servo Micro-step Motor |

| Driving Method | Conveyor & Synchronous Driving Belt | Conveyor & Synchronous Driving Belt | Conveyor & Synchronous Driving Belt | Conveyor & Synchronous Driving Belt |

| Direction & Axis | Three Axis-XYZ | Three Axis-XYZ | Three Axis-XYZ | Three Axis-XYZ |

| Programme Way | Hand Knob or Computer | Hand Knob or Computer | Hand Knob or Computer | Hand Knob or Computer |

| I/O Signal Port | 8 I/O | 8 I/O | 8 I/O | 8 I/O |

| External Interface | USB | USB | USB | USB |

| Power | AC220V 50/60Hz (Optional) | AC220V 50/60Hz (Optional) | AC220V 50/60Hz (Optional) | AC220V 50/60Hz (Optional) |

| Working Condition | ||||

| Temperature | 10-40°C | 10-40°C | 10-40°C | 10-40°C |

| Humidity | 20-90% | 20-90% | 20-90% | 20-90% |

| Dimension(mm) | 430*360*550mm | 550*460*560mm | 635*575*600mm | 850*560*660mm |

| Weight(kg) | 40kg | 55kg | 80kg | 60kg |

Which WellPack Advanced Automatic Glue Dispensing Machine is Right for You?

Selecting the right dispensing model depends on your container sizes, label formats, and production requirements.

To help you decide, here’s a clear comparison of our four WellPack Advanced Automatic Glue Dispensing Machine

| Model | Best For | How It Works | Applications & Ideal Industries | Advantages |

|---|---|---|---|---|

| JT-D3210 |

|

|

|

|

| JT-D3310 |

|

|

|

|

| JT-D3410 |

|

|

|

|

| JT-D3510 |

|

|

|

|

Why Businesses Choose Our Advanced Automatic Glue Dispensing Machine

When investing in a dispensing solution, you need more than just a machine; you need reliability, consistency, and long-term value.

Here’s why WellPack machines stand out:

Maximize Efficiency

Protect Your Brand Image

Future-Proof Your Production

Save on Training & Labour Costs

Durable & Reliable

Space-Saving Advantage

FAQ

Find answers to the most commonly asked questions about our services, policies, and support. Quick help, all in one place

Handles a wide range of adhesives including industrial glues for electronics, automotive, medical devices, and consumer packaging.

±0.01 mm/axis repetitive accuracy with 0.01 mm/axis resolution.

Yes. LCD interface and USB program management make setup fast and intuitive. Optional teaching pendant is available.

No. Compact design and self-contained operation allow easy installation.

Yes. Obsnap Automation offers local installation, training, servicing, and technical support.